Small axe;

Your right,it doesn’t look like there ever was a place for a bracket, which would be fastened after the mast went thru the hull. Does it look like there ever was a place at the mast base for a bracket?

Hey… I have an F21 with the same exact issue… except I do have the L bracket. I just don’t know where it goes! I’ve looked at the mast where and cannot figure out at all where it was placed.

Also underneath the cabin area, I understand there should be a ring or something that you should bolt/screw into the top of the cabin around the mast? I’m missing those parts.

What I did… I took a large pvc pipe and split it. Then used them as shims and hammered them in place to wedge it tight(between the mast and the wedge ring) . It may not be the ‘proper’ thing to do, but it was the only thing I could think of at the moment.

You can find the F25 pdf manual here, ‘http://freedomyachts.org/viewtopic.php?f=16&t=10100’

… under the Manuals and Documentation area…

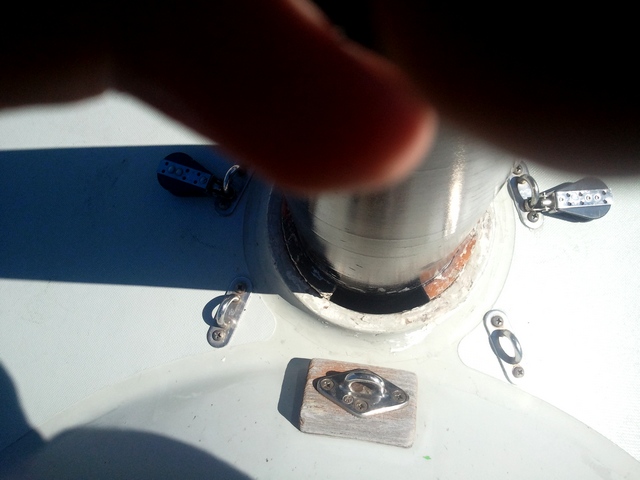

I have posted a picture of my mast base. There does seem to be a hole at the stern end of the base where a rather large bolt could be installed. There is also a matching size end on the heavy gauge green ground wire you can see in the picture. It would be reasonable to assume that an “L” bracket would go there to keep the mast from rotating, but I have been in every corner of the boat cleaning it out, and there is no sign of anything that loos as if it should go there. If anyone out there can post a picture of the fitting, and perhaps some measurements, it would be really helpful to me, as it looks as if I am going to have to make one up to replace the missing one.

Is there supposed to be a matching heavy gauge grounding wire that comes down from the top of the mast? I have downloaded the F25 manual from this site long ago. It is very helpful in some areas and totally lacking in information in others.

I do have a mast collar that looks as if it will fit between the mast and the cabin top. It looks a lot like one of those wax donuts you use to seal the base of a toilet (but a lot harder). The one I have looks as if someone has been “trimming” it with a hatchet!

I would drill a couple of 1/2" holes in the mast, or if that seems too much then use a coulple of ss hose clamps to hold your bracket tight to the mast. Your wooden wedges at the deck will add some anti rotation,.

Joe

(What do you think of the Haarstick spinnaker you purchased?) I went with UK Halsey ($1640.00) . Took for ever to get it to me.

The mast bracket on my F25 is about 6” high, 1” flat at the base and 1’ wide. The hole at the base is open at the side.It is about 1/8” thick. I think one can easily fabricate one from a chain plate. My mast is grounded at the base but just through the mast bracket, no separate wire comes down the mast for grounding. I have to remove the bracket to step and unstep the mast.

(ps. My hull # is 210, looks like you are one ahead of me with 209)

Jim D

When it comes to lightning protection, I think the best way to do this is to run a heavy-guage wire from the mast-head fitting down to the keel bolts. The aluminum alloy mast-head fitting is very conductive, whereas the carbon fiber mast is somewhat conductive. The chance you take by letting the carbon fiber mast pass heavy current is that it will heat enough to be damaged; even cause it to blow up.

Thanks for all the replies and taking the time to measure and take pictures. I really do appreciate it!

I can see the holes in my mast where the bracket like yours must have gone. No such bracket to be found in the boat though. As you say; it should be fairly simple and cheap to make one up. There does seem to be a simpler solution shown on page 12 of the F25 manual available on this site. It has a diagram showing a 3/8" bolt being inserted thru a hole drilled into the very base of the mast and then into the aluminum mast step. What is wrong with that idea? One bolt and you are done, and you don’t have to remove a bracket to unstep the mast.

I can see the argument for a grounding wire from the top of the mast. It has been added to my winter to-do list.

The boat came with a plastic “donut” for securing the mast at deck level. It isn’t big enough to go all the way around though. Does this look normal, or am I missing a piece to the donut (perhaps Davie Jones took a bite sometime in the past)? I was thinking of making up some wooden wedges to fill in the gap.

You are missing a section to the ring. Two years ago when I looked at your boat it was still on board (see picture, recognize the paddle?). You should be able to fill the gap with some wooden wedges. Another project for the coming winter might be making a new ring for your mast. I have seen some pre- made kits to make new collars.

That was a quick response. It seems like the last owner sort of let things fall to pieces - at least in terms of keeping track of all the little bits-and-pieces you need to make the darn thing work.

I’m almost afraid to ask, but if you looked at the boat two years ago what put you off buying it?

As far as I know the last owner only owned your boat for one year. The owner before him is the one that neglected all the rigging. Even though she might not have left Mystic CT since I looked at her, I noticed her registration switch from CT to MA, leading me to believe there was a new owner. When I looked at her she was owned by a college kid that did not sail her. He would keep her in the water without stepping the mast, just for motoring around and hanging out on the waters off Mystic, CT. A few years ago he tried to sell all the rigging because he was not interested in sailing. Luckily his dad talked him out of that idea. The main reason I chose my boat was because she had just been re-powered (only 14 hours on the engine) and I payed basically what it costs to drop in the new engine and she was in sail away condition. I sailed her with my two boys from the tip of Cape Cod to Milford CT in July 2008. But my boat came without a trailer, so I had to shell out some more money to buy one. A big plus for your boat was the galvanized trailer that had seen virtually no use. When I looked at your boat I only got to see the hull. The mast and sails were stored in a different location. The cabin sole was very spongy, leading me to believe the cabin had been very wet. I believe the cabin sole was replaced after I looked at her. I also liked the custom stern rail on your boat. I read you re-powered your boat too. As far as I know the engine was fine two years ago, but that is just based on what the seller told me.

Happy sailing,

I hope you get to enjoy your new boat for many years to come

Jim D.

I got the boat for basically the value of the trailer. The latest seller also told me the engine was in great shape, but the inspector was suspicious, so I had the Yanmar dealer check it out. He said it needed a complete rebuilt so I decided to replace the whole thing with new. The floor had been replaced, but it was a shoddy job, so I went ahead and had it replaced again with fibreglass. Not as pretty as the teak and holly original, but sandy feet won’t bother it.

There aren’t many of these boats out here on the West Coast, so I am having to heavily rely on this forum as a source of information. I have just retired, and am trying to remember how things are done after 20 years away from the water and sailing. I first saw the Freedoms 25 years ago when I was working in England, and have wanted one ever since. I am sure I have a basically good boat here, but it sounds as if your colledge owner is the one responsible for me being short of so many of the little things that are needed to make it work. I am in the process of coming up with a shopping list so that I can give West Marine some more of my money!

If you’re going forward with the bolt idea, I strongly recommend that the bolt and its threads be coated with anti-seize compound (get it at auto supply stores). The mast step is in the bilge (water), and located in an area where your agility and strength could be severly tested in the future if you leave out the anti-seize step.

I think the bolt idea won’t work for me. The diagram talks about tapping the bolt into the aluminum mast base, but when I took a close look at my base it appears to be some kind of hard plastic or perhaps fibreglass resin. Maby when they switched from aluminum to plastic for the mast base they were forced to change from a bolt to the bracket that my boat appears to have had.

I think my best bet now is to get an SS bracket made up to fit the existing holes in the mast and base. I will use some rivets to hold the bracket to the mast for the rest of this year, and then get some proper bolts this coming winter.

I wonder why Freedom changed from an aluminum to a resin step design?

Any ideas where I can purchase a new mast collar to replace the one I have that is missing a chunk. I have gone thru the West Marine catalogue, and they don’t appear to carry anything like them.

what do people feel about melges 24 mail sail compared to full batten freedom sail? this would be for a winged F25?

cheers

A Melges 24 main is close in P, E and sail area; but you already knew that.

You lose the benefits of full battens and the draft may be too far aft, but if it’s cheap go for it and let us know how it works.

anybody have any input on putting a winged F25 on a mooring, with the wing sail the boat with no sail? can this work or not?

cheers,

yarrow

Can anyone give some measurments for the L bracket.

Distance from the Mast to the center of the boat bolt?

Distance up the mast to the center of the 1st bolt and then distance to the 2nd bolt?

Or even better does anyone know were a replacement L bracket can be obtained?

My boat came without the mast bracket. I made a cardboard template with holes matching where the holes in my mast and base were and took it to my local machine shop. They made me a new bracket from heavy SS stock. I forget the price, but it was pretty reasonable, and you do need that bracket to prevent the mast from rotating.

I have two extra brackets. Send me and email if you are interested. Alternatively you could drill a hole straight through both sides of the mast and through the top hat mast step. One long bolt going straight though the mast base will keep the mast from rotating.

happy sailing

Jim D

I have the bracket like the picture above and it keeps the mast down, I also use wood wedges to center the mast in the hole. Between both systems the mast is very solid and does not rotate or move up and down.