I decided to open a new topic, instead of putting all info into big tread on boat projects.

Well, my boat is one big project ![]()

Now I’m in midst of replacing a core on 1/3 of port side of hull. My boat had damage near gunwale. I guess it was a result of either hard docking or storm damage. It was poorly fixed, cosmetically, not structurally, leaving a crack in fiberglass open. Water was sipping in for years.

More pics

Wow, now that’s a project! ![]() All I have to say is better you than me…Sorry…Lots of luck!

All I have to say is better you than me…Sorry…Lots of luck!

– Geoff

Yeah, and it is just one project, I have a few more ![]()

With core I’m moving in right direction, albeit slowly.

I have been working on getting the bottom done on clave’. Finaly towed her to the cranelift spot tonight, in water tomorrow. Just cut into the hull to install a depth sounder, in hull style, dug out balsa core and thank God it was dry. That is one big mess you are into.

I have about 10 days to the key west regatta and lately the wind has been perfect for my CK. Out of the north and blowing about 15knts by the afternoon. We’ll see how long that lasts. Good luck with your project though! Numbknots

Good luck with your race!

I did a few “control drilling” in my hull, just penetrating inner skin to see how core is. My starboard side is dry. My port side, besides the area of delamination, the one I’m fixing now, have some moisture in it. I guess, as soon as water find it’s way in, it starts spreading throwout the hull.

Interesting thing that port side also have some blisters. It confirms a theory that blisters grow from inside out…

Wow! Big project.

I feel your pain I had to redo do a section of the transom on my F-40 CK (there are picts somewhere on this board). But at least when you are don you’ll have the satisfaction of knowing that you have a sound boat.

Best of luck with your project

alex

Someone asked me once “Are you done with your boat now?” My reply, “No I still have a little money left.” It F#*%&ing never ends. Numbknots

Numb, perfect, absolutely perfect. I must be close to being done with my boat then.

I didn’t have much money to begin with ![]()

I make some, I fix something in the boat…

It doesn’t look like I’ll ever be able to afford anything bigger than 28 footer. So, I decided to buy a fixer-upper and fix it by my retirement, which is still 20 years away.

I bought it, I fixed rotten cabin top and all systems, sailed it a lot.

Now, besides core, I replacing tanks, head, water system, cutlass. Working weekends. Hopefully, I’ll put the boat back to water by july.

There are more projects coming.

Cabin sides need recoring, new ports and woodwork, next winter, I guess. I didn’t open centerboard trunk yet and board is starting making noises, seems like it is getting loose. Paint job is due after all fiberglass structural job is done.

Motor will need attention sooner or later.

New sails…

I have a few drawing of windvane. I don’t feel like building it yet, but one day I start making one…

Yes, it will never ends…

RU,

Working on boats so you can go sailing…The fixer uper…Now after my experience with this same “Classic Sailboat Ploy” I beleive your way ahead letting some other schmuck do all that work and buy it from them for a dime on the dollar. Or better yet the old adadge “If it floats , flys or fornicates, your better off renting”. Numbknots

Numb, you probably right. However I enjoy working on a boat. We have winters here, up north:) what else to do. I wouldn’t be doing my repairs in may and june if I didn’t decided to take a break and sail around Florida(row and bike too)

http://www.tampabay.com/sports/outdoors/eight-who-dare-the-ultimate-florida-challenge-race-tests-paddlers/1077300

http://www.silive.com/southshore/index.ssf/2010/05/arden_heights_sailor_completes.html

It took me 26 days to circumnavigate Florida, so now I’m paying a price of working on a boat instead of drinking a wine on my own floating waterfront.

Here is a pic of a crack which was a source of all my core problem. As I said, boat had a damage. PO just filled a crack with filler and gell coated it. Repair didn’t hold, crack opened again. It looked like typical hair crack, however it was letting water in.

I can not do any structural repair from inside, there is not enough surface for glassing. So I have t glass it from outside. More work for me.

Hey CrazyRU,

Just had a survey done on a ck33. And the survey says! Big section of starboard topsides around chock, moisture meter reading way high. Surveyor is doing destructive meter readings today.

When did you notice your problems? Were the areas delaminated ( obviously from the pics some of them were).

Why can’t you laminate the core to the hull from inside and reglass the inside?

Good luck, wish me luck ![]()

I have a couple water leak issues on my boat just about the same place as yours. Seems like inside the cabinetry above the sink there is water getting in. Maybe from toe rail or that stantion base. My toe rails are aluminum, I see yours are teak. Better re-bed that stantion base and check the toe rail caulking as that may be part of your problem. Numbknots

Chandler, I’m laminating the core from inside. I broke my galley apart, to get an access to the hull

I had to fix small crack both from outside and inside. That crack was letting water inside of sandwich.

I was searching for my “perfect” boat for 4 years, and during 4 years I looked at about 6 or 7 cat ketches F28 and F33. All boats were priced well below market value, I was looking for cheap boat. All centerboard models had had sinking cabin top where weight of centerboard compress it. It is obvious design flaw. 5 boats also had delaminated/rotted areas of topsides. (mine included). It puzzled me a lot, I’d expect to see delam below waterline, not above it.

Now, after cutting into my boat and removing significant parts of fiberglass and furniture, I come up with some understanding why it happened. I’ll post my disturbing finding soon…

RU,

I also had the same area of core damage around the center board sheave at cabin top. That was an easy fix compared to what you are into now. That area on rail always seems to be the low spot on deck where water will accumulate and eventually find its way under toe rail.

I was thinking of cutting through the base of the aluminum toe rail to let water escape. That would open the base of toe toe rail extrusion and then that could be filled with 5200 or even glassed. Its to bad they didn’t form a simple raised edge in the mold where the toe rail attched to the deck eliminating the standing water issue. Numbknots

Working with a core. Making sure that every rectangular is fully covered with epoxy. It makes it waterproof. No manufacturer will do it, too much work. Also balsa absorbs liquids as tristy man. Covering it with epoxy makes later adhesion better.

Spreading thickened epoxy on outer skin. Using serrated spreader to make even coat of glue.

New core is in everywhere, good…

New inner fiberglass skin is in work.

New skin. note solid fiberglass area for thruhull

As you can see, I dissected my boat in many places.

Overall impression of quality of labor is good to excellent. I really didn’t see any sloppy pieces of boatbuilding, even in places not meant to be seen. I said boat building, not boat engineering.

I cannot blame workers doing layups and piecing all together, they did their job well. I cannot say same thing about guys who designed the boat. Even if we put aside an idea of using balsa as a core, there are many places of somewhat questionable technical solutions.

One I pointed already before in another tread – I had aluminum tank firmly foam glued into a hull before inner liner and deck put together. There was no way to get badly leaking tank out without breaking floor and fiberglass moldings.

Also I think I understood the case of wet topsides. I drew a picture to explain my findings.

While trying to fix a crack, I sanded through gellcoat at very edge of topside, just before hull to deck joint. I found may areas where fiberglass had many voids and it was very weak. Note. I didn’t see bad fiberglass job anywhere on my boat , just at very edge of the topside.

It is almost impossible to lay a fiberglass, especially thick one at 90 degrees angle without either making big curve or applying a pressure on both sides.

Fiberglass just doesn’t want to confirm to the curve, it is a nature of a beast.

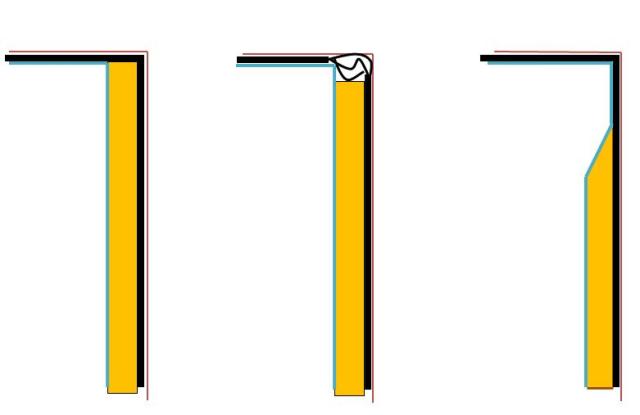

Look at my drawings, from left to right., they are self-explanatory, I hope.

On left it is how engineering guys designed it. In middle pic is the reality. On right how it should be done.

Hi CR,

Very good explanation and drawing. While moving around along the hull in my F44 (1981, hull #4 of 26 built) I only found balsa core stopping short of the deck edge, hull bottom mid seam / keel and along the transom to hull connection, so every thing was done like it should. However they put a flat surface transom light (Perko) in a 2" hole in the transom. The core was not covered in the hole, therefore most of my transom core is wet and an area around the hole is completely rotted away. The transom laminate is so thick that I don’t foresee structural problems.

When was your boat built? Was it perhaps an early one, or a late one?