I looked longingly at a SS mix elbow but passed due to me replacing the current elbow about 12 years ago. I did use my endoscope to inspect the interior of the elbow when hoses were off. It was rough for sure but still plenty of cavity for water flow. Having said this. When the elbow goes bad one better have sails ready to go cause a clogged elbow is full stop time. Don’t ask me how I know.

BTW, my cheap Amazon endoscope has been a life saver more than once. I also used during this project to view the interiors of my aforementioned stringers so I could get my wrench on those godforsaken bolts.

Worst part is I ran out of cuss words halfway through.

If you’re interested in a good discount on a used 316SS elbow, I’m going to be offering mine for sale once I swap in the new one I bought. Nothing wrong with the elbow, I just wanted the outlet to be rotated 90º to the right for a straight shot to my muffler. In the 3GM30F the exhaust is on the starboard side, so it makes sense to have the mixing elbow is aligned with the exhaust bend. However, on the 3YM30AE the exhaust outlet is on the port side, which meant draping the hose across my transmission (which slowly wore a hole in it). I might have been able to rotate the mixing elbow 90º with a big enough vice, a torch, and a huge wrench, but I figured it would be easier to just swap in a new one. Here’s a link to what it is: https://hdimarine.net/product/gm-kit/

Yours for $150.

Look at all that room you have! You could park a car in there!

Thanks very much for the offer, I am tempted. However, after having gone through the agony of the last four weeks, with everything buttoned up and tested, I am loath to even contemplate an elbow replacement and the inevitable hose rerouting at this point. I just want to get out on the water, lick my wounds and chill.

I will be coming out in a few months to replace the seal, May change my mind at that point and reach out to see if you still have it, Again, many thanks for the offer.

Just a few after action thoughts on the motor mount replacement.

first, I am a little concerned about the almost rigid hose my boatyard used to connect the current lasdrop seal to the stern tube when the shaft was replaced two years ago. As a result, almost all engine vibration is borne by the seal as a result of this inflexible hose coupling. I am comparing to the flexible hose I received from Warren Rived as part of the Tides coupling kit which is much more pliable. Can’t help but think this rigid hose is bad for seal durability. No matter how fine the alignment, vibration is vibration.

second, When I did this job I was unable to verify shaft alignment in the stern tube nor was I able to change out the 15 year old cutlass bearing. Those really need to be good before this job can be called complete.

I plan to have the boat out in Juneish timeframe and will do the appropriate shaft centering and bearing replacement. I will also add the more flexible hose to the shaft log/seal joint. After that I will a do new alignment. Hopefully this will yield a solid end to end set up and extend seal life.

Mike, I hear that! My 2024 season was severely limited by a cracked shaft seal, and it was a nightmare. I couldn’t find anyone to haul me out for over a week while it was leaking. Once the seal was repaired and I was back in the water, I had one good sail before my starter died. That’s when I found the hole that the transmission had nearly worn through my exhaust hose—not an enormous deal, but disheartening discovery nonetheless.

Two more points:

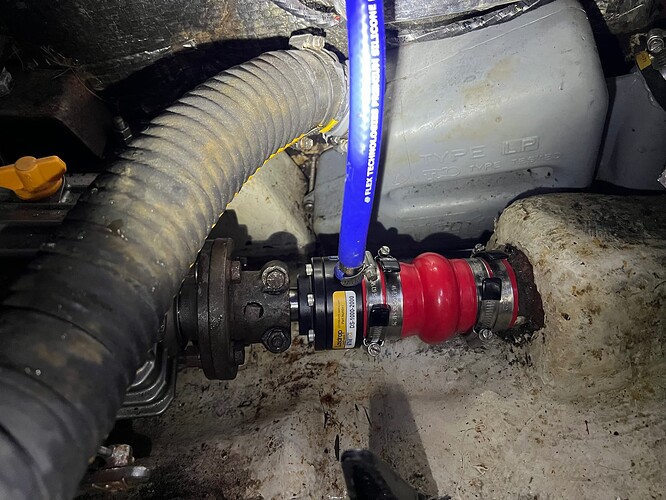

- The hose that comes with the Lasdrop is definitely too rigid. The aforementioned cracked shaft seal was a Tides Marine, my second since 2021. Both of them formed a crack at the threaded hose fitting for cooling water, and I decided I needed something a bit beefier. The Lasdrop seal feels much more robust, so hopefully I won’t have the same issue. I had to cut off about 1" of the body of the seal to make it fit (and I probably should have cut 1/2" more), but otherwise it fit fine. However, as soon as I felt the hose that it came with I knew I would be reusing the red articulated hose that came with the Tides seal. It’s much thinner than the Lasdrop hose, and thus a lot more flexible.

- Are you sure you would need to re-route your exhaust hose if you were to switch to a new elbow? As long as the elbow is oriented like the picture above, it should basically be an identical swap. Not trying to pressure you into buying mine, I just want to figure out if it will fit on a 2GM20 the same as a 3GM30. I thought so, but you know more than I do about that engine.

RZ, that’s an interesting set of pictures. I am surprised that you have so little space between the seal housing and the coupling…looks just like mine. Misery loves company.

And, I’ll tell you, great minds think alike. I was taking another look at the tides seal and hose coupling vs my existing lasdrop after the mount replacement. I began to wonder why the hell I was changing seal housings when, maybe, all I need to do is change the hose coupling to compensate for some (or all) of that engine vibration. When I tried to carefully scope it out I realized the tides was not going to improve that spacing at all. Not only that, but the lip seal itself is essentially identical in both seal housings. I also note when the tides seal wears out and starts leaking, the entire seal and housing must be replaced while the Lasdrop allows for seal only replacement at a cost of about $30.00 for the seal ( I have one spare aboard already). It does appear you may have a bit more gap between the seal housing and the stern tube which is where the gap should be IMO.

Another thing I note is that your shaft flange is split. Mine is not and those two flange bolts adjacent to the seal are not present on my flange, just the big set screws. However, things are so tight, I am unable to completely withdraw the hex screws from the face of the Lasdrop to allow the face to be removed and expose the lip seal. Why would I want to do this? Because doing so would give me an additional 1/2 inch of shaft to work with during alignment. The seal is pretty secure by itself so long as the boat is not being powered. I have considered machining away a bit of the flange (1/4" or so) to, maybe, find enough room to mount a spare seal directly on the shaft. That would be sweet and can only work with the Lasdrop set up. Another option would be to find a slightly less long flange assembly. A third option would be to cut back the barb on the seal housing and trim back the stern tube in order to widen the gap between them. I could do all this when I am out of the water.

I find this mechanical layout a real PIA. I wish FYI had simply designed the boat with the engine moved forward an inch or two. I actually looked at this possibility when I had the mounts out but it was going to be major surgery and I didn’t feel comfortable taking it on.

With regard to the mix elbow, Yes, My layout is very similar (now) my now box looks much like yours with the articulating input barb. I also had to be careful about chafe against the transmission and I will be closely monitoring this as I do some longer term testing in the next week where I plan to motor about 20 NM out and back to my house. Having said this, I remain adamant about my position re changing out the elbow at this time…despite your very attractive offer. You should be ashamed of yourself for tempting me with this right now ![]()

I replaced my mounts and did the alignment myself it’s doable if you’re patient and precise. Mount swap is simple; alignment takes time but isn’t overly technical. Use feeler gauges or a dial indicator, go slow, and recheck once the boat’s back in the water. The Tides seal is a solid DIY with the boat hauled. If you’re confident and prepared, you’ll be fine.

I am sure everyone is sick and tired hearing about my mount replacement but I promise this is the last update.

I have now motored about 80NM on the new mounts.

Boat continues to run smoothly with no problems. Did have an unrelated alternator bracket failure but they was easily fixed. Nothing to do with mounts.

The interesting finding is the seal is leaking a lot less than I anticipated.

As I mentioned elsewhere. A friend borrowed my boat and went agound in mud. He used significant power forward and reverse prop over a period of about 30 mins. After this episode leakage decreased about 70%. What???

I am not complaining mind you, but this lower rate of leakage has been sustained for 60 NM. It is pretty close to being tolerable. I fabricated a pump dry bilge pump for the shaft well so I could keep water from migrating elsewhere when the boat is heeling. I have a small waste tank for whatever water is pumped out so I can visually observe the amount of water pumped over time.

One of these days I will send some pics and adescription of my dry bilge pump lash-up. I am pretty proud of it.

Meanwhile here are two not particularly good pictures of the new mounts.

If I recall correctly you have not hauled and gotten to replace the seal yet.

I am wondering if that grounding may have temporarily shifted the point where the shaft and seal meet. I do recall varying amounts of water ingress over time. At 1/2 gallon an hour my nerves could no longer stand it and had to haul.

The main reason I am writing is that I had to replace the shaft and leaking seal due to a wear spot on the shaft right where the lasdrop seal rode. I was surprised that a tiny groove of 5 thousands of an inch was all it took to cause the leak. Thus the existing shaft could not be reused.

So when it comes time to haul and do this fix then a new seal, coupling, shaft and cutlass bearing will most likely be necessary. Unfortunately the old shaft had to come out to get the specs. So extra time to get the new shaft was needed. Also Keeping the coupling keyway short was very helpful.

Others have written here about this scenario so I was warned about the extent of the project.

I went with the Tides and flex hose because that is what Paul Dennis advised. Although I liked the idea of the lasdrop in place spare seal arrangement. But there was just not enough space to fit it.

Anyway I hope all goes well and you have a great season.

Correct. I have not hauled out yet, and with greatly reduced leakage am comfortable with current situation. I am getting maybe a cup of water an hour. My dry bilge (really a dry shaft well) system is on a timer and runs for 10 seconds per hour which is enough to keep her dry while motoring. Very little leakage while sailing.

I do not want to hear about a shaft replacement :). I just did that 1.5 years ago. What I did not do was the Cutlass bearing which was not showing too much wear based on a shaft shake test. If I have worn a groove I will be an unhappy camper.

If I did groove the shaft I would be looking to shift the shaft fwd or aft a bit. worst case have a machine shop take 1/2 inch off the shaft. i have some wiggle room re length.

Btw. I have an open silicone tube run from shaft well to bilge. If needed I hook that up to the shaft well uptake barb and I can completely dry out the main bilge. I like to keep those keel bolts dry when not out and about.