Quick update for you Camino.

I finally completed the mount replacement, alignment and exhaust rebuild with new water box. Couple of outcomes so far:

The Good:

1.When I ran up the engine both neutral and in gear I was really surprised with the reduction in vibration. I had assumed I might get a little improvement but it was rather dramatic. Big win on this issue!

BTW, you are probably aware that there are different “softness” specifications for Yanmar 2GM mounts. The F30 is equipped with two 100s and two 75s (I have no idea what the numbers refer to, but lower is softer) . All information I was able to glean, including from Paul Dennis was that the 75s went aft and the 100s went forward. There is some online debate on this issue similar to the famous to grease or not to grease the old syntron shaft seal (donlt grease!! according to the manufacturer), Anyway, when I removed the old mounts both the port mounts were 75s (fore and aft) and both the starboard mounts were 100s. What the hell?? I figured maybe engine torque or some such? I don’t know, but I went with the data and Paul’s recommendation and am extremely happy with the result.

Alignment was difficult to accomplish with high confidence because, on my boat, the distance between coupling flange and the shaft seal housing is so tiny that I could not completely get the shaft coupling lip (that Pearce alluded to) free from the transmission coupling. I could rotate both independently but could not separate them fully. I aligned as best I could and got to about 4 thousandths around the whole coupling face. I also had some vertical misalignment which I adjust out with the adjusting bolts atop the mounts. This all took three days of fussing around.

Note: you need to allow the mounts to settle before adjustment according to experts so I did that over a long weekend before I attempted any fine tuning.

The bad:

-

I still have seal leakage which I had hoped might be reduced or eliminated with proper alignment. I do have a new seal purchased from Warren River so I’ll have to come out in a few months to deal with that. I have some mast work and bottom to do at that point so I’ll just add the seal to the pile. Fortunately I have no leakage when at the dock.

-

Freedom really dropped the ball IMO with regard to how they installed the mounts. I mean the original install was OK I assume but they made zero effort to provide for mount replacement. Both access and mechanical are sub par IMO.

On my boat FYI punched un-secure bolts from the bottom of the engine bed stringers. So when I removed the nuts holding the mounts to the stringers the bolts wanted to fall into the stringer cavity with very limited access to retrieve them, much less hold onto the damn things when reinstalling the mounts.

I wound up having to cut a 2.5 inch hole in the bottom of the stbd aft cabin bulkhead in order to get a wrench on the aft most bolt during re installation. Same in port side although a hole was already cut, it was too small to obtain access and I had to use an oscillating tool cutter to expand it.It was impossible to fit a drill inside the sink cabinet to expand this hole AARGH!! This took two days to accomplish. The good news is the next time I need to replace mounts I can get access to the hardware.

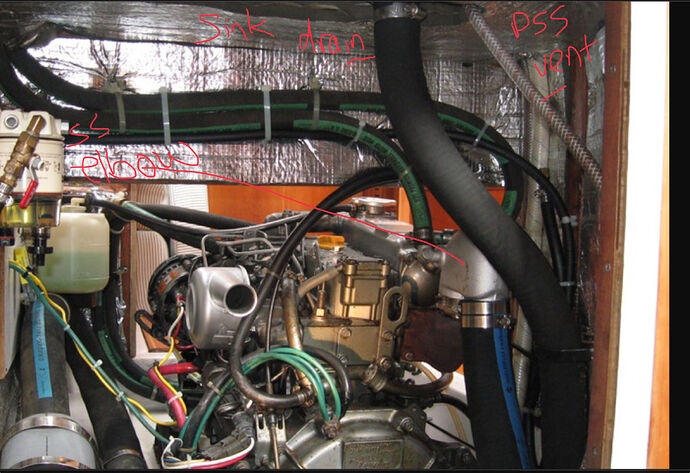

On a positive note, the project did lead me to replace old and worn exhaust element in the engine bay coming out of the mix elbow. I purchased a new Vetus water box with an articulating input flange which allowed me to get rid of two bulky galvanized plumbing elbows. Now I have a straight shot from the mix elbow to the water box, sweet.

Another interesting finding was that the old water box had decades of accumulated rusty bits in the bottom chamber. I had always wondered why I got a stream of rusty looking water when I first started up. Mystery resolved. Now, on start up, nice clean raw water from the get go.

So I just finished stringing the new bilge pump hose from the bilge through three lateral stringers,though the engine compartment, under the water heater through the lazarette and ready for trimming and hook up to the pump itself. OMG what a PIA that was, It is ribbed hose and tight penetrations,I am bruised and bloody but, by God, that hose has been routed!

I’ll post some pictures of all this in a follow up.