I am so tired of leaks! The word leak should be eliminated from the English language and replaced with “pain in the ass”.

Anyway, I had just completed replacing motor mounts and refit of the exhaust system with absolutely no leaks (after one or two false starts). I went up the SF Bay which required a good number of hours of motoring and found my engine well full of water. AARGH!

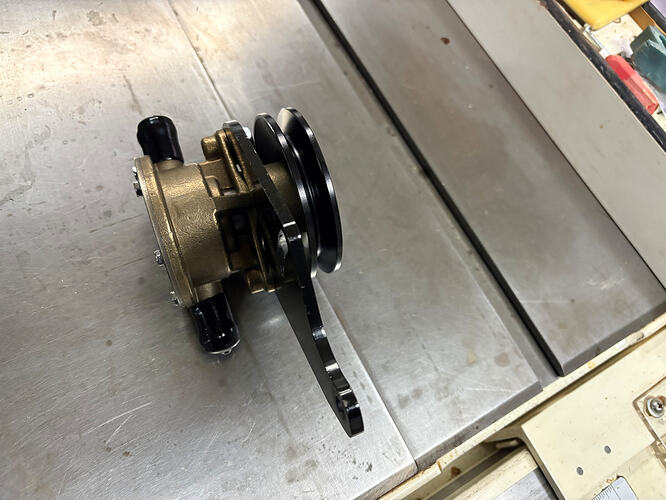

After some TS I found the Raw water pump was leaking. I thought this would be easy. it is probably the input or output hose. Nope, it looked like it was coming from the cam screw at the bottom of the pump. Tore everything apart and, as a bonus, found a trashed impeller (shame on me) and a very badly worn cam. So I bought a rebuild kit which included the cam, screw , screw gasket and impeller, the rest of the rebuild parts would go in my spares kit.

Got this completed, re-installed the pump and the leak was worse.

WONDERFUL!! now what?

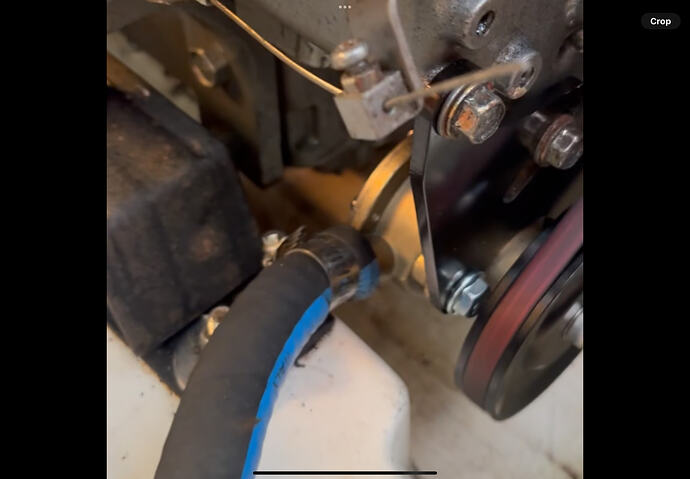

So I started the engine, got out my flashlight and started looking for the leak for the third time. It turns out it was coming from a weep hole in the pump body. What the heck is that for? I never knew that hole existed. It turns out this weep hole is behind a lip seal (called the oil seal for some reason) and a large rubber “water seal” and before the pump bearings. I assume this is designed to protect the bearings if the seals go bad. Water leaks out vs flooding the bearing cavity.

Anyway, pulled the pump out - again - and started a full rebuild using the kit which I had, fortuitously, already bought. It took some work to get the bearings off the shaft and to get the shaft Assembly back into the housing but, amazingly, it all came together and passed the leak test.

Just a heads up, if you have a mysterious leak from the raw water pump be sure to check this weep hole. If the pump has not been rebuilt for a long time, those seals are likely toast. Mine had at least 26 years on it. Amazing it lasted that long.

Another interesting note on this. The lip seal noted above is exactly the same design as the lip seal used in my Lasdrop shaft seal. The pump seal is smaller diameter but looks identical, it does have an integrated housing seated in the pump body unlike the Lasdrop where one can pull out only the lip seal itself.