I did a 40 nm engine mount checkout voyage which went really well in terms of mounts and exhaust plumbing. However, I did experience a broken alternator bracket which was completely unrelated to the mounts and easily fixed. I also spent a night at anchor during which I realized my two 110AH house AGMs were compromised to the extent the bank would only deliver about 50 AH.

I did not spend a lot of time troubleshooting. I bought cheap AGMs a couple of years ago with the thought I would be upgrading to Lithium at some point in the future when I got up enough courage to face this new technology. Yea, I know, it’s not new, but it is to me. So that point has now arrived.

Anyway, to celebrate the end of the engine mount saga I decided I would launch into a house bank LFP upgrade, how hard could it possibly be? More famous last words have never been spoken ![]()

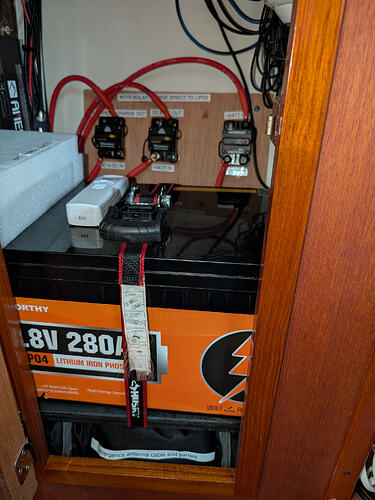

So I bought an Ecoworthy 280 AH LFP battery. It is a cheap LFP but a fellow on YouTube I respect (Will Prowse) tested and tore one down to look at build quality. He gave the battery a thumbs up in the “cheap LFP” category.

Standard LFP batteries are not good start batteries (although they have been used to start) so I kept my old AGM start which was still in pretty good shape.

Since only my solar controller charge source had a Lithium profile I connected this directly to the LFP battery. I connected shore power and regulated alternator to the “charge bus” which charges the AGM start and also provides power to a Victron DC to DV charger which converts the AGM charge profile input to a LFP appropriate charge profile. BTW, the Victron can be configured for a variety of chemistries. It also has Bluetooth which allows this configuration to be done from the phone. The Ecoworthy battery also has Bluetooth. I downloaded the “overkill solar” app to access the battery and the integrated Battery Management System (BMS) so I can see all the BMS settings, cell voltages and so on. It is a real game changer in terms of visibility into what is happening with your batteries.

Anyway, I got it all put together and, after a week, I think I am sneaking up on an understanding of how it all works, Especially the charging and cell balancing element which took some serious time staring at what was happening with cell voltages as I applied charge current , did a discharge session, rinse and repeat about twenty times.

One thing I found is that there is an incredible amount of BS flying around regarding LFPs. There are a lot of amateurs (like me) pontificating without having a clue what they are talking about. Warning issued.

So I have completed testing on shore power and solar charging, They work, I have not tested alternator charging yet. That will be a biggie. One sweet thing about the Victron is that its max current transfer is 50 amps but it can be throttled all the way to zero in 1/10 amp increments. This is important because one feature of the LFP battery is its ability to accept a LOT of current for a long time. I have a 125 amp alternator on a serpentine belt but my alt probably will not like running at a constant 50 Amps for 5.5 hours while the LFP charges. I do have a belt manager on the Balmar ARS regulator so I have a second way to reduce alternator output but that requires some hands on work with the regulator while the Victron config is just an app away.

One new concern with LFP is the presence of the BMS. This electronic device (in my case embedded in the battery case) monitors temp, input and output voltage and current and cell balance (and probably other stuff) constantly. If it detects a fault in any of these parameters, it will shut the battery down until the fault is cleared. Now this is an interesting feature. I can remember a time approaching Pillar Point Harbor in the fog at midnight. If I had had LFP and the BMS had decided this would be a good time to dump the battery that would have been interesting. I do have a backup plotter on internal battery but everything else goes dark. I have to figure out a way to switch the +Bus to the AGM battery in an emergency.

I realize I am babbling but I thought I would keep you all updated on how this goes.

Some interesting LFP related links:

Will Prowse videos/battery reviews ++

https://www.youtube.com/results?search_query=will+prowse

DIY Solar forum (has a Marine category + much good info/resources)