Leak found.

New fittings today. I have 3 weeks to get the motor running and back to the slip. Summer rates on the hard kick in and triples the price.

And back to it.

Well after 5 surgeries in the past 11 months I am finally getting my strength back to start back up again.

Pulling the boat this Saturday to place on the hard for the winter. I have a slow “Seep” that I need to fix. Afterwards I will start up projects as winter allows in regards to drilling holes topside. I think insulating the cabin top will be my next progression minus the locations I need access.

Currently working on replacing both sails and the running rigging. I have another post in that section.

Yea made it to Anchorage driving thru a winter storm. Now off to the Evil Store (West Marine).

Well back to it. Today was a multitude of things.

-

Cover the cockpit and secure the A-frame for high winds.

-

RV antifreeze the motor. If curious I poured the antifreeze down the raw water hose and turned the motor by hand until I had it coming out the exhaust elbow. I had the exhaust hose removed for the following.

-

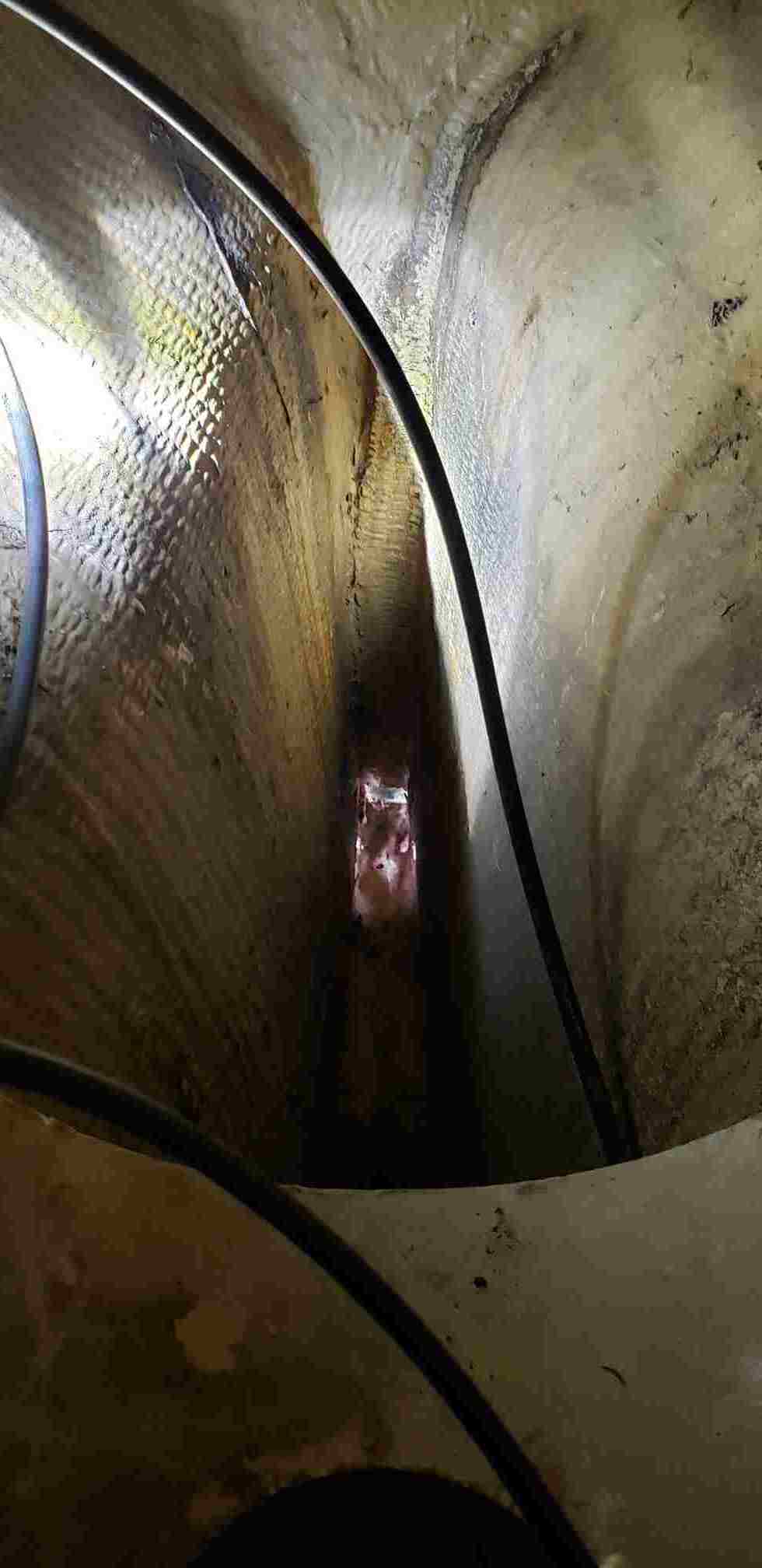

Start to look into a chronic leak (seep) at the lower gudgeon. If the bilge pump stopped it fills the bilge to the floor boards in 5 days. This was how I found the leak to begin with. Photos to follow.

Cockpit cover. We average 30-50 feet (900-1500 cm) of snow each winter.

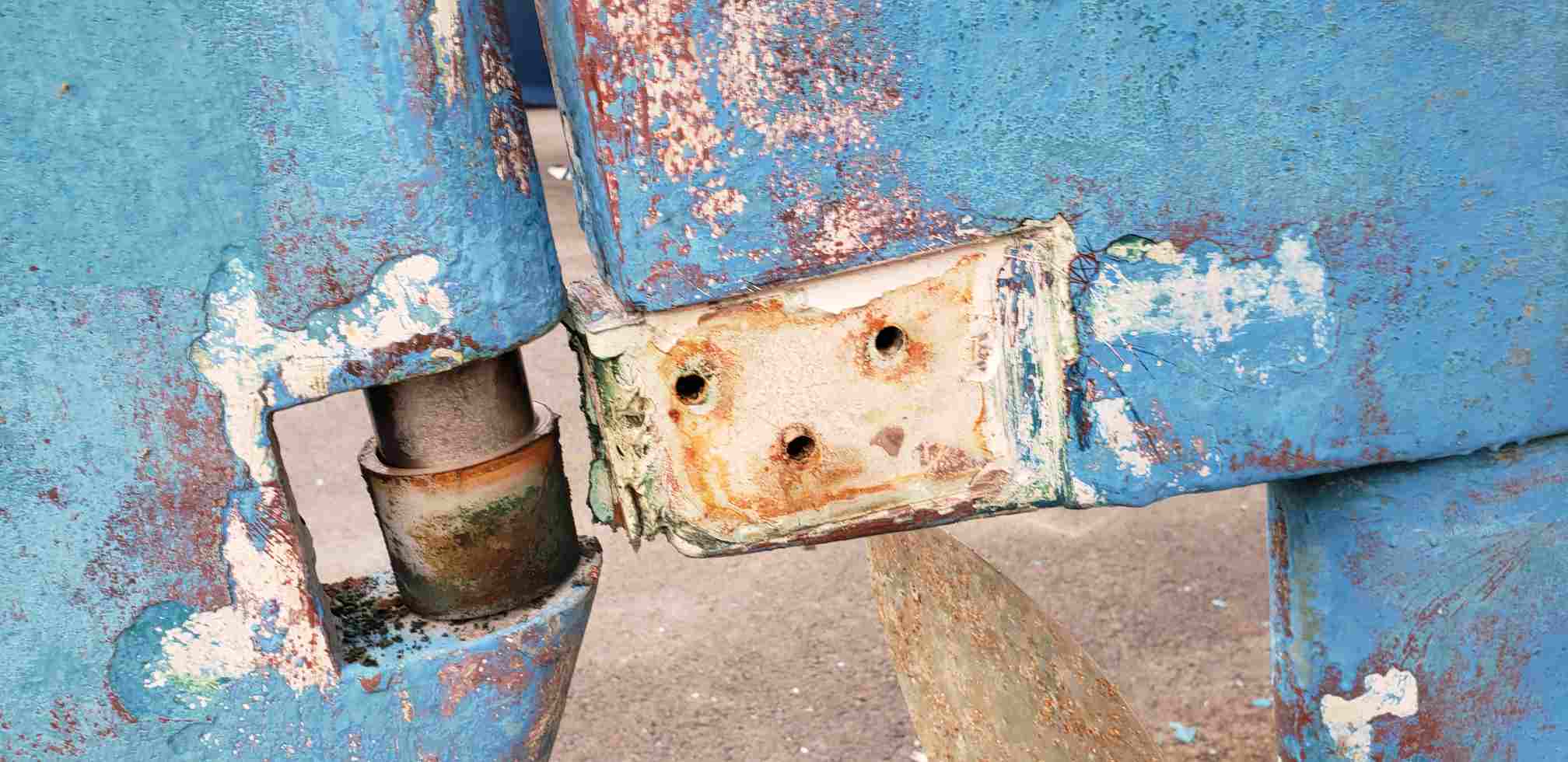

Da leak location. Not quite sure “where” from the outside. It seems like it is seeping from the bottom.

External views.

Another view

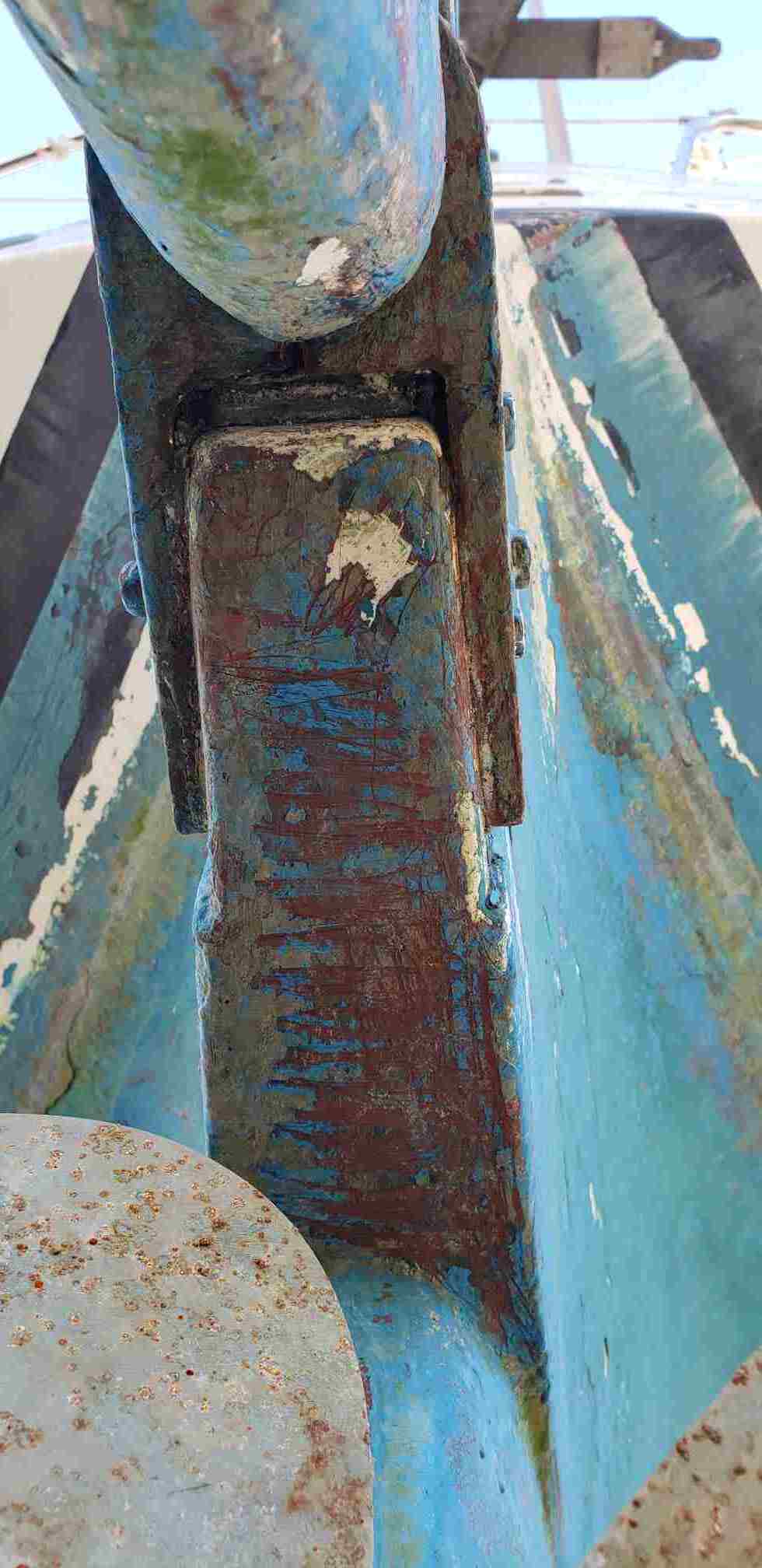

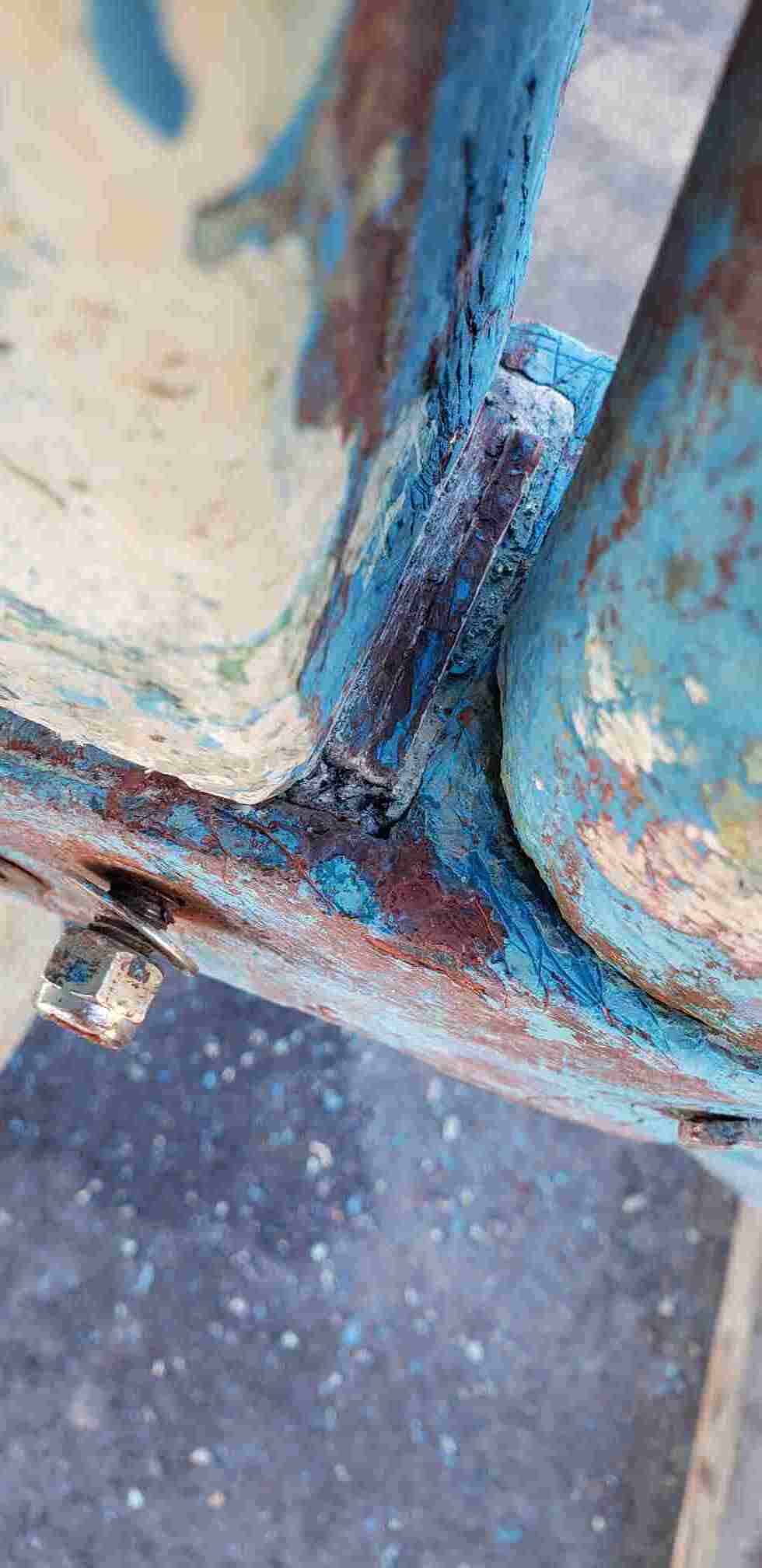

And the other side. I didn’t see any obvious cracks. Could be behind the wedge between the gudgeon and boat. I am suspect of the bolts…

[quote=Sailing-61-North post_id=53973 time=1632712732 user_id=6247]

Cockpit cover. We average 30-50 feet (900-1500 cm) of snow each winter.

[/quote]

Hi there,

I don’t know if this is allready your winter setup, but as you were measuring for new sails i wanted to pin out that the whishbone booms are not horrizontally rigged. Usually the aft of the booms sit way lower than displayed on your picture. Arround 1-2 feet above the coachroof.

Sorry if I am pointing out the obvious.

Cheers.

Yep winter setup only.

Anyone know the weight of the rudder?

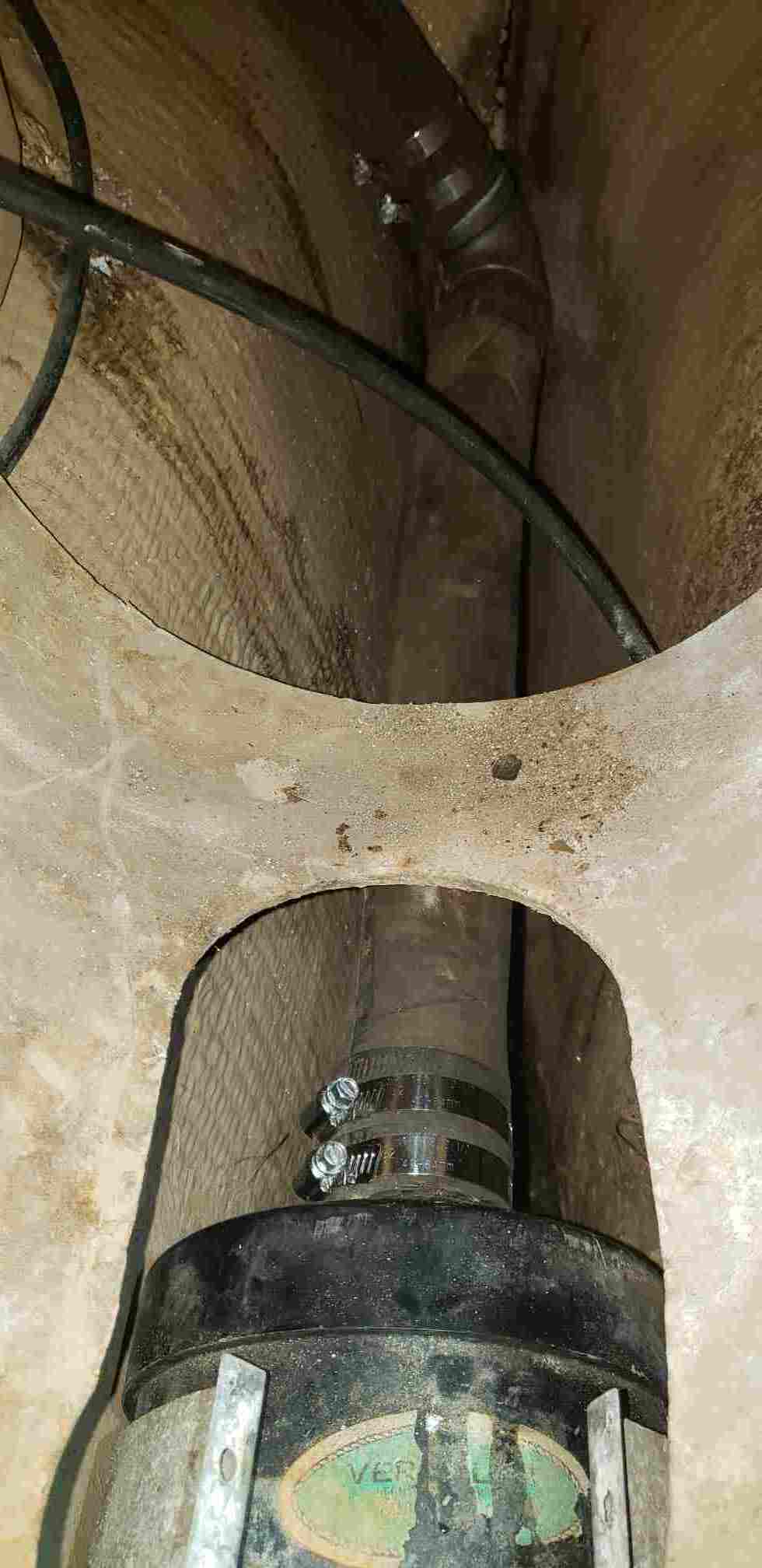

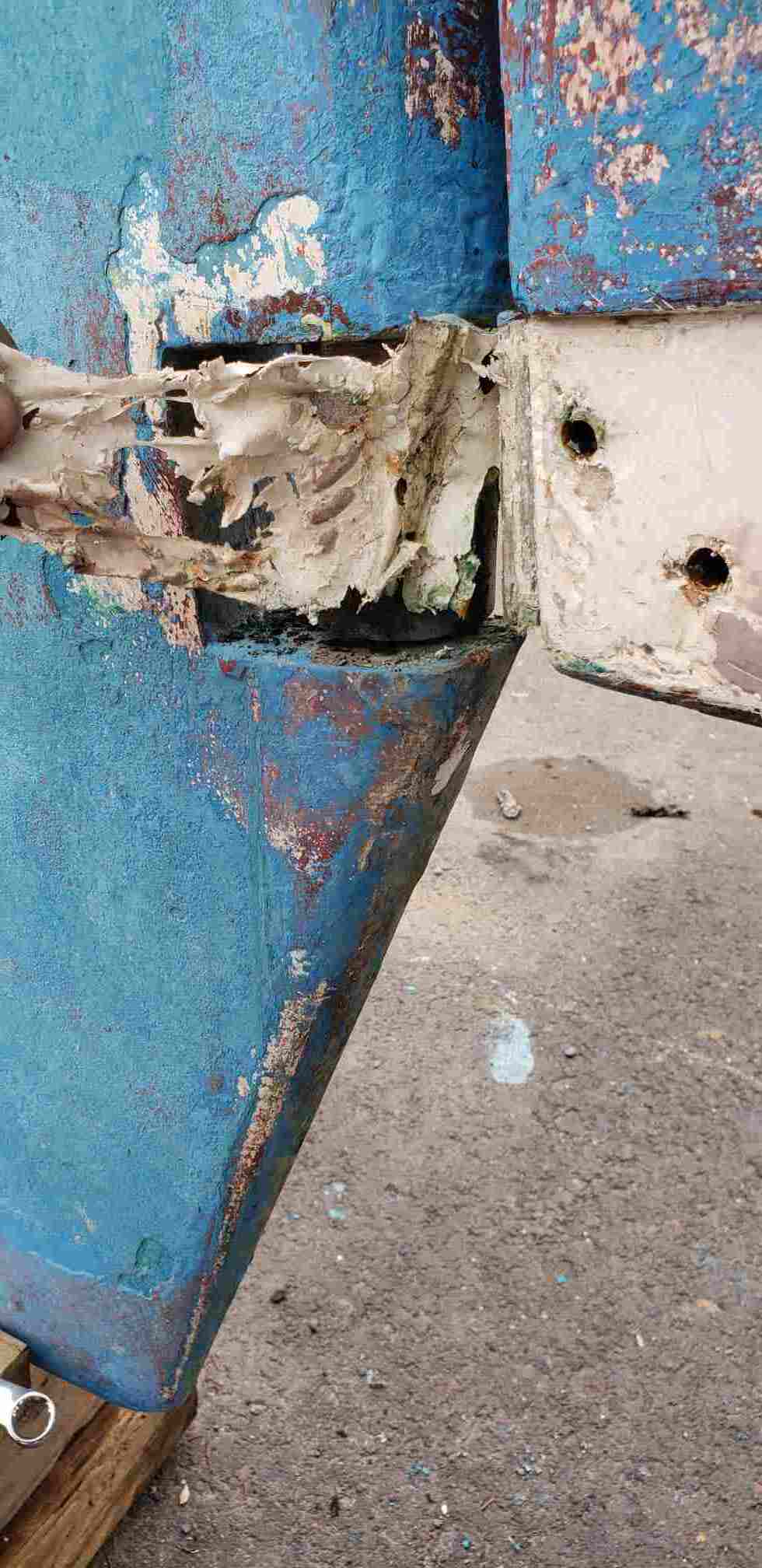

Pulled the bolts for the bottom gudgeon, one at a time, for inspection. One of them had wallowed out threads. Below the middle bottom bolt

is my seep. I don’t see any obvious cracks on the exterior. I still want to pull the gudgeon to inspect behind it.

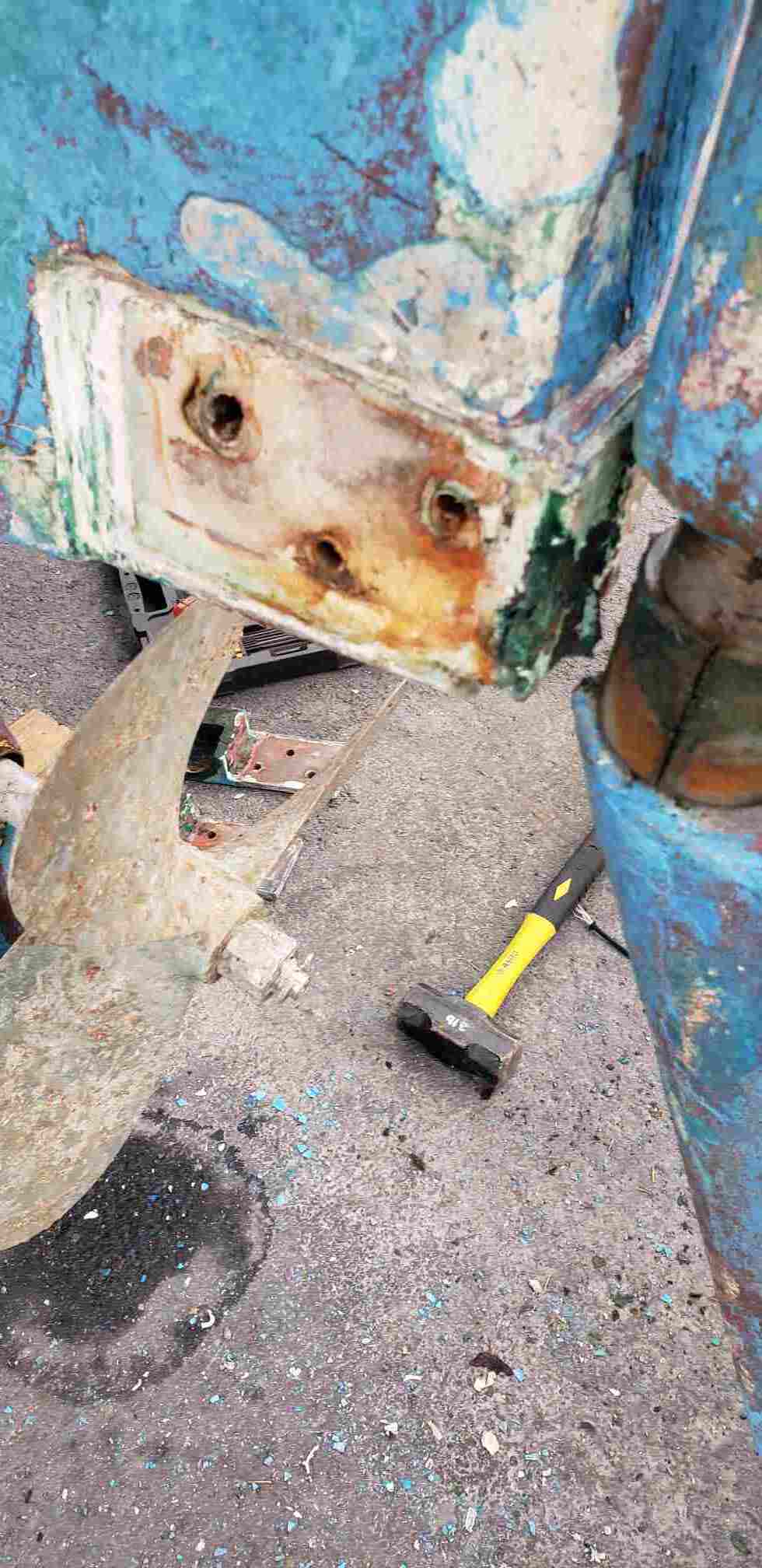

Removed the gudgeon today. All of the holes were wallowed out. If it doesn’t snow tonight I will head down tomorrow, grind a 12:1 area and lay new fiberglass. Also depends on Temps. Was 33 today.

More photos before and during removal of the 5200.

And more. Wallowed out holes and threads of bolt.

Nice job balancing the rudder. I’ve always used a car floor jack to work on mine, but i need to do a 3" lift to get it out of the lower gudgeon.

If you are considering replacing the bolting, or for that matter, any st. steel hardware below the water, go with a 316 grade to avoid corrosion.

I used some 316 pipe to sleeve my holes.

I assume the picture showing the bolts inside the bilge were the gudgeon bolts. That’s not going to be the easiest place to seal the joint. You could glass it all over on the inside.

Make sure to keep the rudder all aligned… Some personal experience ![]()

Thanks for all the updates. Not going to make you feel bad with a weather report from the SF Bay.

Erik

Yea I was surprised it wasn’t solid back there. Not sure if I will line the holes or what. VERY tight spot from the inside. Either way I have some fiberglass work to do and winter is basically here. That portion may get put off till April. Just formulating a game plan. I still need to remove the spacers on the front but need a second set of hands to “push” the rudder over an inch.

[quote=bad post_id=53985 time=1633277844 user_id=5392]

Nice job balancing the rudder. I’ve always used a car floor jack to work on mine, but i need to do a 3" lift to get it out of the lower gudgeon.

If you are considering replacing the bolting, or for that matter, any st. steel hardware below the water, go with a 316 grade to avoid corrosion.

I used some 316 pipe to sleeve my holes.

I assume the picture showing the bolts inside the bilge were the gudgeon bolts. That’s not going to be the easiest place to seal the joint. You could glass it all over on the inside.

Make sure to keep the rudder all aligned… Some personal experience ![]()

Thanks for all the updates. Not going to make you feel bad with a weather report from the SF Bay.

Erik

[/quote]

You don’t me asking. What size sleeve (ID or OD) and did you keep it just long enough to have it somewhat recessed? I was thinking of something along this line for two of the bolts. The back one is partially into the very after aspect of the transom so not sure yet what I will do there.

Another option would be to dam off the very back, sand the shiny side and pour a solid block of thicken epoxy but given the amount of epoxy needed I am worried that would created too much heat once it started to kick off. I know - jello…

Thanks

Was thinking about placing internal patches on both sides but shy of cutting an access hatch into the cockpit sole there is really no way I can fit back there - I tried.