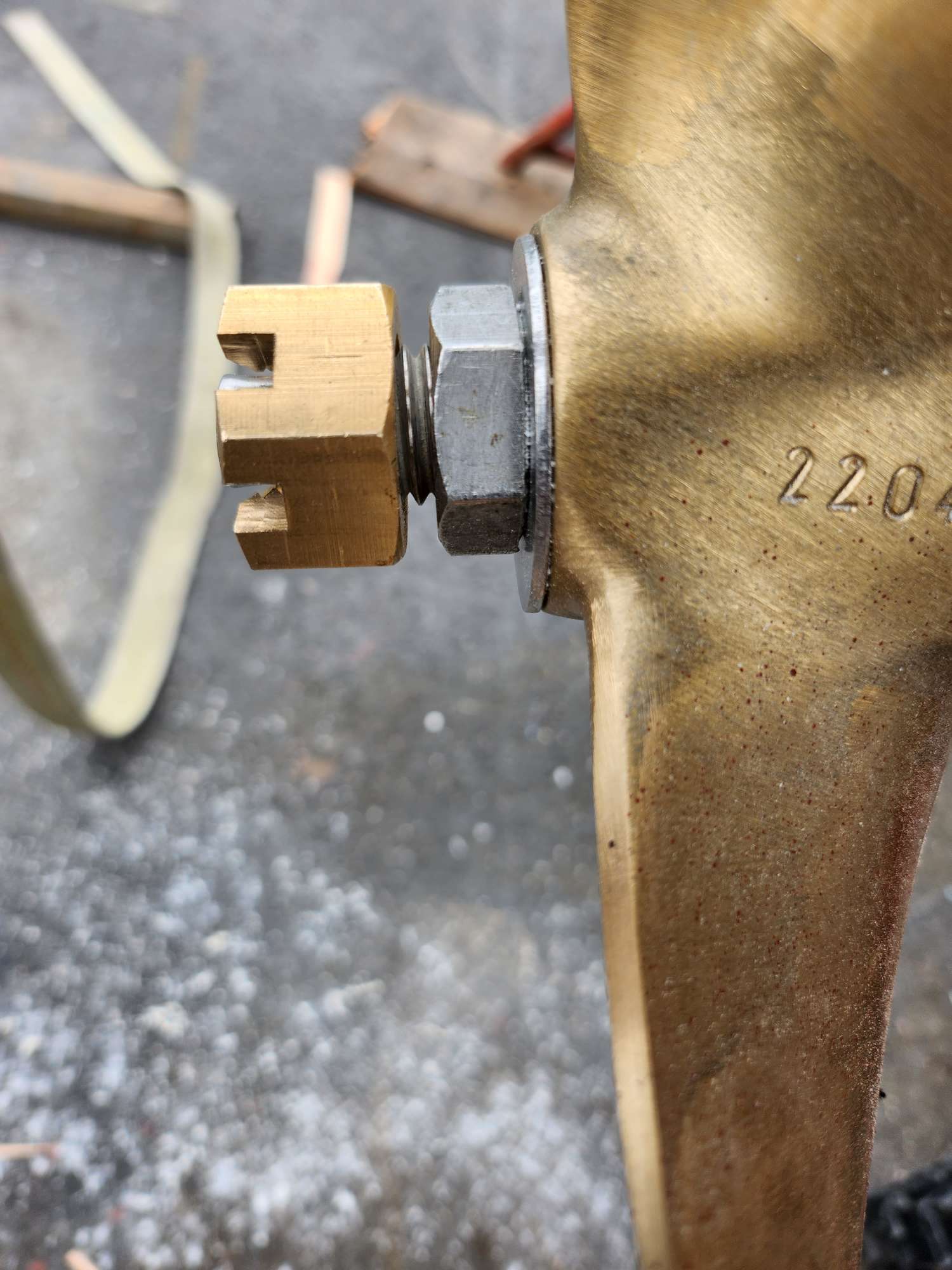

And thy Castle Nut in need of washers…

General idea… Have to stop due to I am down (2) 9/16 wrenches in the bilge, beneath the engine housing…

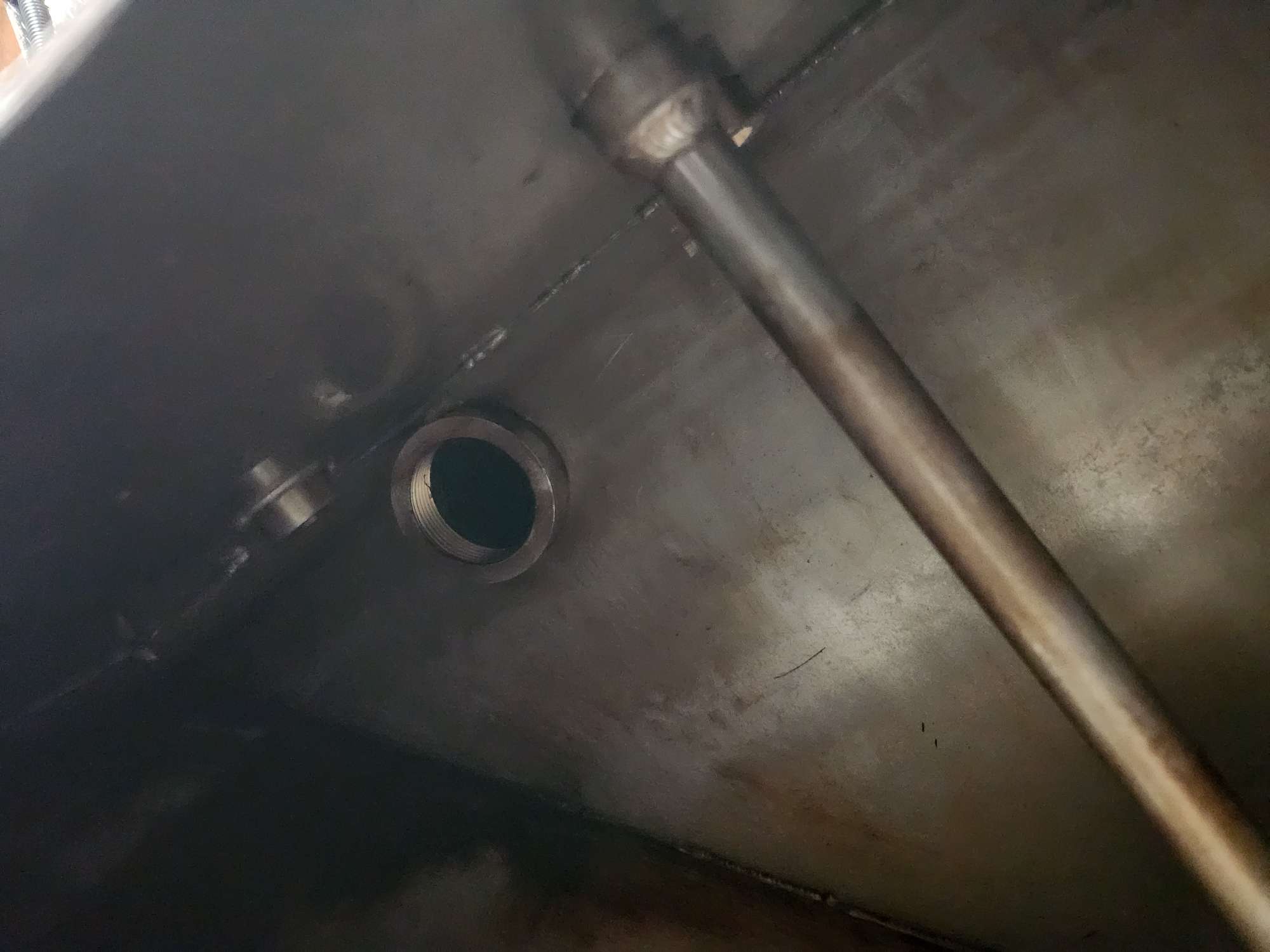

More fun. Drained all of the fuel and cleaned out what I could reach. Poured a few gallons of Acetone and let soak for a few hours before removing that.

More photos

More photos of bowsprit

Most unique bow sprit on this earth ![]() love it and your work! Keep going!

love it and your work! Keep going!

As soon as I get the bottom gudgeon on I am putting the boat back in the water. Tired of paying double fees. One for my slip and one for being on the hard.

Our harbor has a drive down dock with cranes. When ready will tow my boat over there with my dinghy, have the new motor in the back of my truck and “lift-lower” into my boat. Not too expensive ($80-hr) charged in $20 per 15-minute intervals. AND we are not regulated like alot of other harbors…

Just waiting on a new plasma cutter so I can make new mounts.

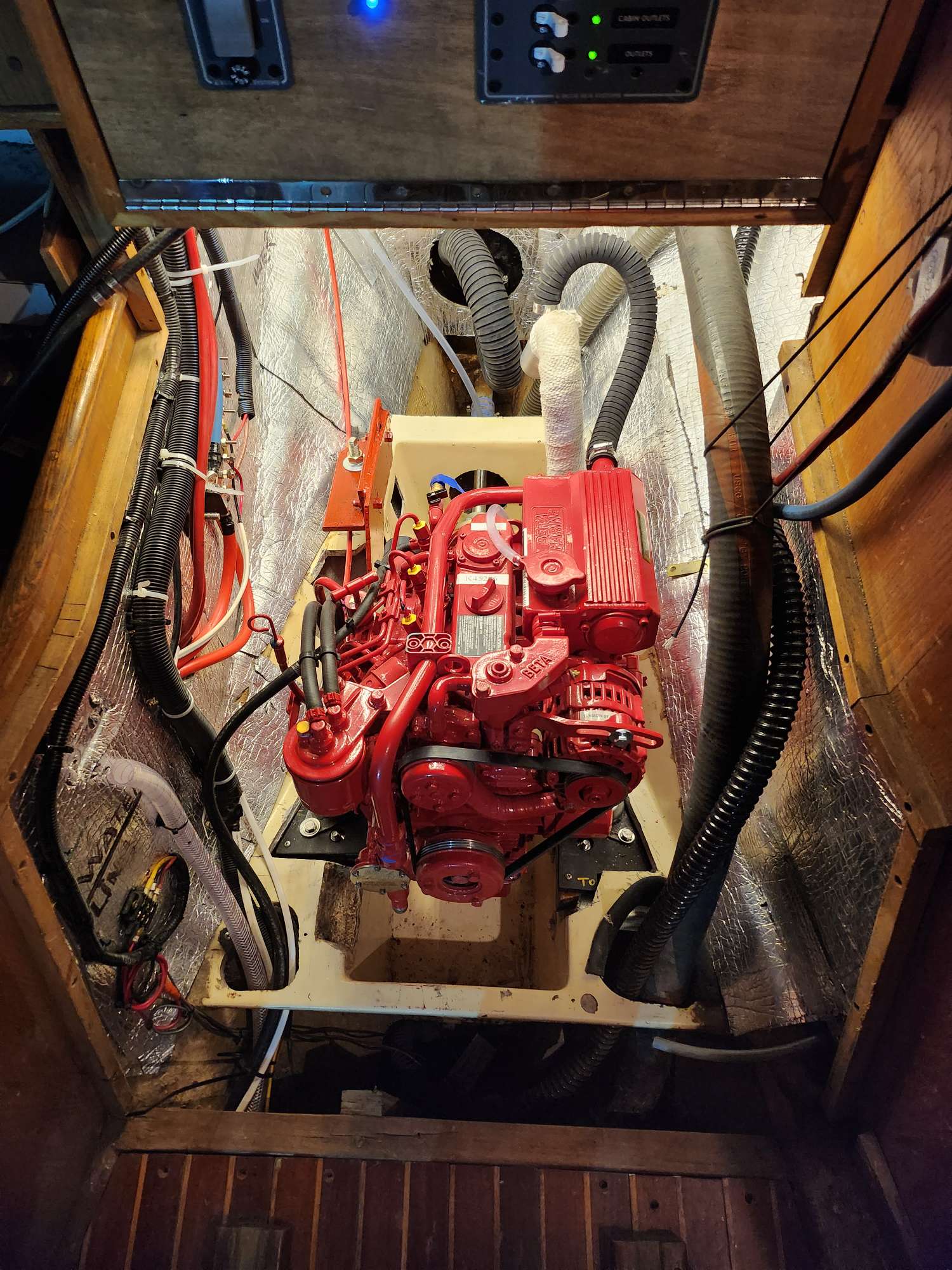

Nothing like waiting till the last minute. Winter is coming yet got s break in the weather to lower the motor onto the cabin sole. We have a “Marine Technology Class” at our local college and they were asking about an inboard project. Works for me and them. Just a few things to prep.

Jacked up and resting for now. Will need to remove it for some fine tuning but for now it’s out of the way.

So… the big red dragon is in. Congrats! My goodness, you´ve done a lot of work on that boat! ![]()

I have all winter to fine tune. Once the motor is done I can focus on other functional items with anticipation of summer use.

Motor is in. Took the weekend getting it all aligned. Still have to attach the fuel lines, battery, wet exhaust and raw water.

The biggest con was going from a yanmar to beta and having to recreate the motor mounts.

And she’s running. Some fine tuning for rpm and water heater but so far good to go.

Engine looks great - benefit of going for the wee 25. One point to ponder is that there should be an air vent in the raw water loop between the heat exchanger and the exhaust injection. I ran the air pipe up the inside of the aft end of the cabin with an overflow into the cockpit which discharges water at above 2500 rpm. Sorry that I don’t have a photo.

And another thing - now is the time to check access to the fresh water (with anti-freeze of course) drain from the cylinder block. Beta engines are notoriously bad for this - see the Beta Owners Group on facebook. Also check all the wiring for chafe against numerous jaggy bits on engine. They should have been secured by Beta before the final paint spray but my main umbilical to the multiplug and on to the control panel needed extra protection under the air filter. There is a recent horror story of an expensive short behind the alternator - sparks, smoke and melted wires.

If you have shore power heating to a calorifier, you should put an easily accessible stop valve in that part of the fresh water circuit as your shore power will waste itself slowly heating the engine while you’re tied up in harbour. Several KWH per day.

And I hope you know that the Morse control wires need to be loose and able to move where they go through the cockpit floor otherwise the revs may not drop as you pull back to neutral. Some ingenuity required to reduce the water ingress - like a tube glassed in above the floor.

My carbon-based stern-tube gland does not tolerate any oil, meaning I can’t spray all the couplings to keep down the surface rust. A big mistake to choose that one.

Yep I did get an air-vent when I purchased the motor. Just haven’t gotten around to it yet. Been a bit snowy in December. We are sitting at 200 inches (500cm) so for the past month my day has consist of work, get off work, drive home and jump on tractor for a few hours each night.

[quote=arrancomrades post_id=55878 time=1701676671 user_id=5990]

And another thing - now is the time to check access to the fresh water (with anti-freeze of course) drain from the cylinder block. Beta engines are notoriously bad for this - see the Beta Owners Group on facebook. Also check all the wiring for chafe against numerous jaggy bits on engine. They should have been secured by Beta before the final paint spray but my main umbilical to the multiplug and on to the control panel needed extra protection under the air filter. There is a recent horror story of an expensive short behind the alternator - sparks, smoke and melted wires.

If you have shore power heating to a calorifier, you should put an easily accessible stop valve in that part of the fresh water circuit as your shore power will waste itself slowly heating the engine while you’re tied up in harbour. Several KWH per day.

And I hope you know that the Morse control wires need to be loose and able to move where they go through the cockpit floor otherwise the revs may not drop as you pull back to neutral. Some ingenuity required to reduce the water ingress - like a tube glassed in above the floor.

My carbon-based stern-tube gland does not tolerate any oil, meaning I can’t spray all the couplings to keep down the surface rust. A big mistake to choose that one.

[/quote]

I am dealing with my morse cable not wanting to return to idle. It’s my next priority to deal with. Those other items I will mark on my “to do check list” and work my way thru them.

I actually got the calorifier to plumb into a hydronic heater with a fan. You can never have enough heat up here.

Off the top of my head I’m not sure where the drain is. I will have to look.

Back to the grind. One more week of school (teaching) then a part-time summer job (week on / week off).

Been rigging the new sails - photos to follow.

New motor is in. Anti siphon done. Had to drill and thread the new coupler to match the shaft. Each night after work I spend an hour or so with projects

Also had to retrieve the mizzen haylard.

Been working on the 20 hour break-in. Very light wind but what the heck. Still figuring out line configuration.