just dismasted on way to mexico from hawaii nobody hurt more info later

Oh dear… Good job you’ve got 2…!

What material is the mast made of, & what were the circumstances that led to this, if I might ask?

mast is made of carbon fiber , cause of break unknown, light conditions when mast broke

I deleted the duplicate post in “Random Chatter” to keep all conversations related to this in a single post.

First off, so sorry that this happened, but I’m glad that no one was hurt. Did you continue to Hawaii or return to MX?

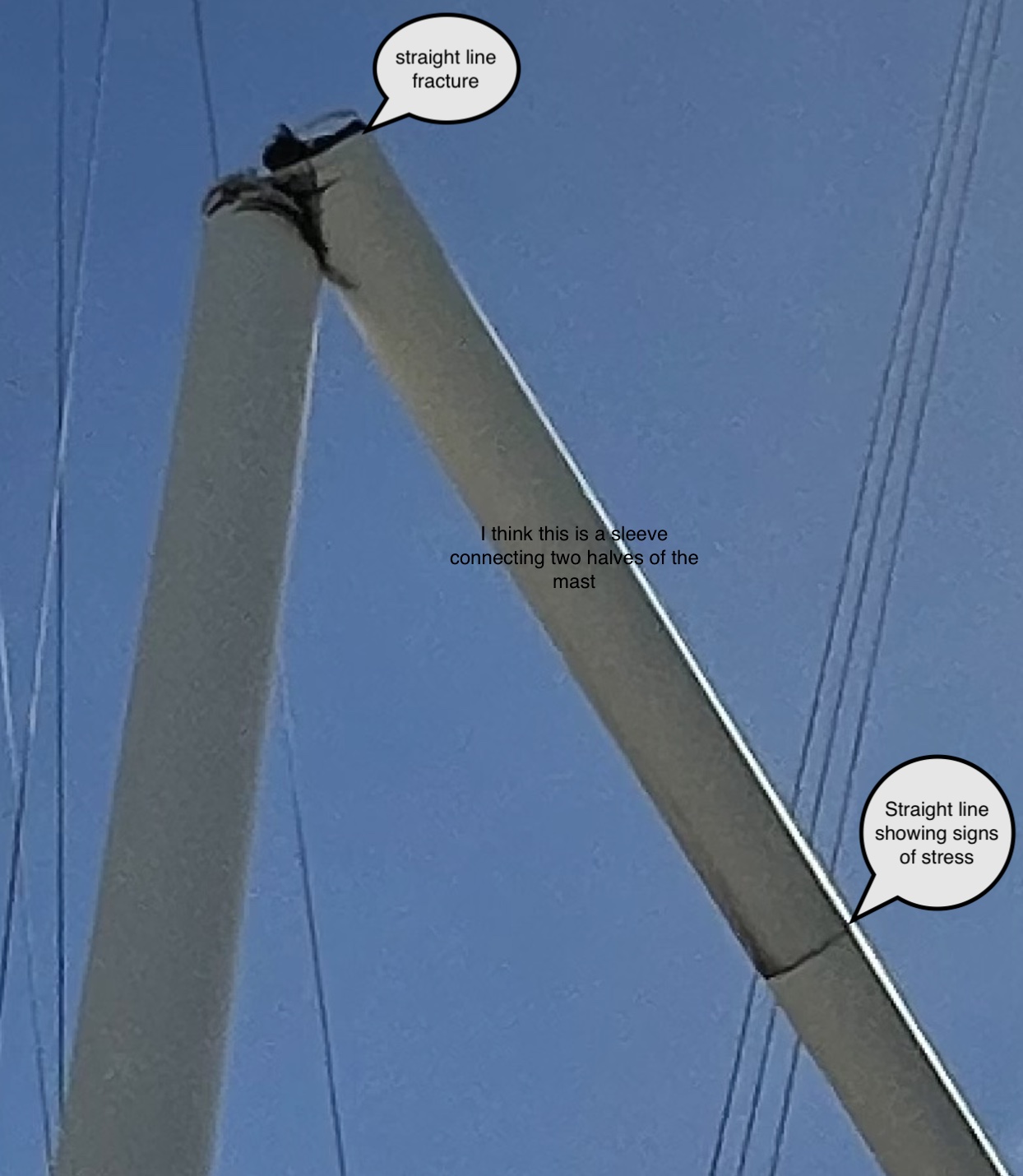

Next, I see what appears to be another crack higher up on the mast, and from the stains coming down from it, it doesn’t appear to be new. What’s the story with that?

And, did you ever fly a spinnaker? If so, from where on the mast?

– Geoff

hi geoff , thanks for your concern, mast came down about 1/5 the way to mexico so we opted to motor back to hawaii, there is not another crack the place you are referring to is a slight bulge from the splice { mast was made in 2 parts ) and is where the spare halyards slap and wore off the white paint, , no spinnaker was ever flown from this mast / no fittings ever installed on mast other than sail track and no lightning strike , mast was visually inspected and sounded with a rubber mallet every 8 inches prior to every departure, mast came down in 12 knots of wind beam reach and calm seas , Adam

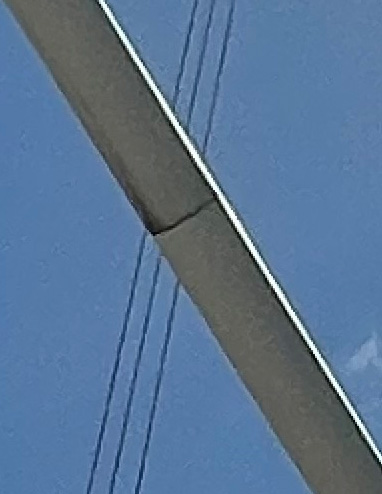

This is the area I was asking about. There certainly does seem to be something other than halyard slap going on. Not that it really matters, as that isn’t where it broke, but I’m just curious. And I’m just amazed at how clean the break is.

we have had extensive conversations with eric schonberg and physical testing by carbon fiber expert . the best we can tell is failure by fatigue,

I had the same questions as Geoff. Is this the original mast? What year was it? That it came down in 12 knots seems really strange. Is the main mast built the same? I am so curious about this because there is so little information on failure of these masts. My single one from 1988 seems to have been built to withstand 10 gorillas jumping on it simultaneously. Glad I’ve never tested that.

Sorry for these troubles. Very glad to hear all are safe and you were able to get the boat back.

This is the other area that I was curious about. From my untrained and inexpert eye, it looks like the mast was built in four sections, but maybe the connecting pieces were superficially laid up?

It looks to me as though both the fracture point and the ring/stain above it correspond to a sleeve used to join the two sections of the mast. If so this is always going to be a point of weakness. However if laid up correctly, this should not be a problem, the fact that the joint is visible and has staining says to me this was a manufacturing fault.

I too am interested in the failure of these CF masts, I know my F21, from inspection is a single layup but am thinking ion getting F28, with longer masts.Does anyone know if manufacturing these masts in two (or more) sections is the norm?

This is the first I’d heard masts were originally laid up in multiple pieces. I have heard; however, about sleeving a mast to repair a a break. Certainly Eric Sponberg would know this history of the original masts (but maybe not the 39s…?).

So is this a Tillotson Pearson mast?

I don’t know about your F39, but I know the TP carbon fibre masts on the F35 / F33 have known issues with circumferential cracking, for which Eric Sponberg devised a remedy.

Had yours ever shown sign of that circumferential cracking? Has it been through Eric’s remedial process…?

In a way, the fact that a carbon fibre mast with known issues should break might not be that surprising, if those issues were never treated.

What would be far more interesting,though, is if it had failed despite having been through the remedial process…

I’m also curious as to why you’ve had the mast “inspected prior to every departure”? Was there something that you were concerned about? What experience did the person have with carbon fiber masts that was doing the inspections? Given that this occurred in light conditions, just after departure, I would ask for my money back!

the black ring has been there for 20 years is not a crack , has been inspeceted in detail before every passage and is where the white paint got rubbed off by the spare halyards [ mast was originally black and subsequently painted white] mast was made in two pieces at factory and then joined together As per eric schonberg . mast failed 1 foot below the factory splice, hope this clears it up Adam

Freedom 39 ph masts were constructed in 2 pieces and then joined together at the factory ( as per eric Schonberg) you may confirm this with him if you like, dont know about the other boats , the splice consists of an approx 1/8 inch x 3 foot internal sleeve, the wall thickness of the sleeve is supposed 1/8 inch and the wall thickness of the mast at this point was specked at a 1/4 inch and has been confirmed by carbon fiber expert prior to repair , the black rings that you see are not cracks but are rubbed off paint by haylards and other gear (masts were originally black and subsequently painted white ) the mast failed at approximately 1 to 2 feet below the factory splice anyway , The carbon fiber guy could not find any defects in the layup, hope this clears it up a little Adam

Freedom 39 ph masts were constructed in 2 pieces and then joined together at the factory ( as per eric Schonberg) you may confirm this with him if you like, dont know about the other boats , the splice consists of an approx 1/8 inch x 3 foot internal sleeve, the wall thickness of the sleeve is supposed 1/8 inch and the wall thickness of the mast at this point was specked at a 1/4 inch and has been confirmed by carbon fiber expert prior to repair , the black rings that you see are not cracks but are rubbed off paint by haylards and other gear (masts were originally black and subsequently painted white ) the mast failed at approximately 1 to 2 feet below the factory splice anyway , The carbon fiber guy could not find any defects in the layup, hope this clears it up a little Adam

[quote=adam post_id=55107 time=1670043622 user_id=6405]

Freedom 39 ph masts were constructed in 2 pieces and then joined together at the factory ( as per eric Schonberg) you may confirm this with him if you like, dont know about the other boats , the splice consists of an approx 1/8 inch x 3 foot internal sleeve, the wall thickness of the sleeve is supposed 1/8 inch and the wall thickness of the mast at this point was specked at a 1/4 inch and has been confirmed by carbon fiber expert prior to repair , the black rings that you see are not cracks but are rubbed off paint by haylards and other gear (masts were originally black and subsequently painted white ) the mast failed at approximately 1 to 2 feet below the factory splice anyway , The carbon fiber guy could not find any defects in the layup, hope this clears it up a little Adam

[/quote]

So the sleeve is 3 ft long, & the mast failed 1 - 2 ft below the splice. Can’t quite visualise what the mechanism would be, but that does sort of seem like it could be relevant, does it not? That maybe the failure occurred right around the bottom end of the sleeve…? Which would presumably be 1.5ft from the splice, no…?

Have you been able to take a close look at the 2 sides of the failure? Is that the case that you have sleeved section above the break, & unsleeved mast below? Or was the sleeve itself broken?

Could it be that the stiffness of the sleeved section prevents the spar from flexing uniformly along that section of its length, thereby somehow transferring heavier point loading around the ends of the sleeve…?

Just thinking out loud. Probably gibberish…

i am not composite engineer but, it seems reasonable that however well made the splice was made and because of the xtra thickness there that then would be somewhat of a hard spot and transfer more flexing/ load directly under the splice Adam

when you look inside the mast with a flashlight you can clearly see the splice and the break was well lower than that by about 3 feet

boat was purchased from original owner about 12 years ago masts were in original condition and no circumferential cracking was observed at that time, we then painted the masts white in situ with a laytex elastomeric paint specifically to prevent further uv exposure. adam