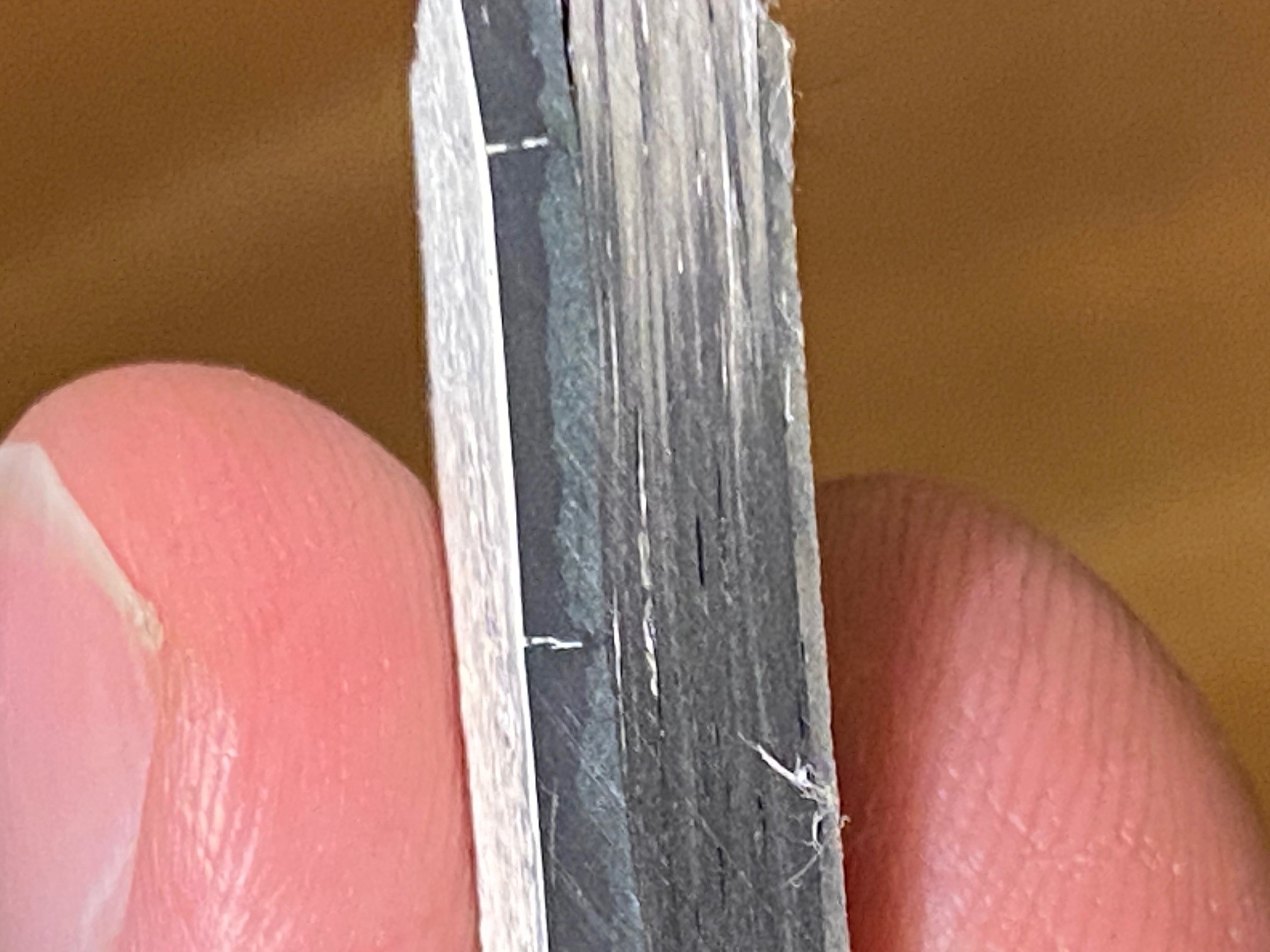

5X edge grain (you can see some voids here too)

5X Cracking

50X (circumferential cracking thru the fairing but not thru the FG)

Repair sequence:

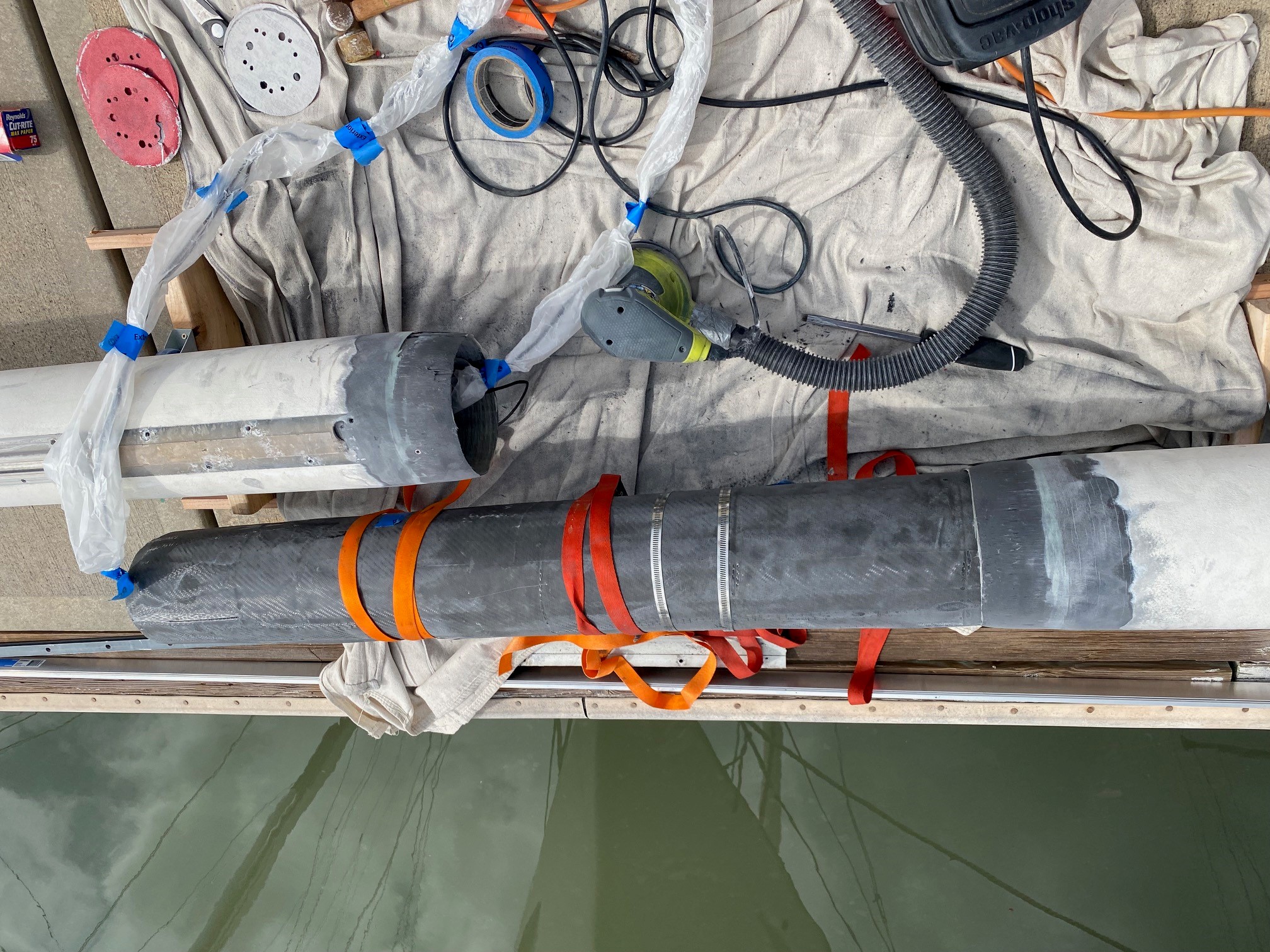

Mast laid out on dock with 20” broken zone removed. I made small stands with wheels to support the mast along the length.

Ends tapered at 16;1 Sleeve dry fitting. Wax paper around messenger lines. Sleeve is 3/16” thick and 60” long.

Glued up with High density filler and epoxy. Aligned with angle iron and the mast track. Clamped with strap clamps and large hose clamps.

First layers of layup. I alternated about 3-4 layers of unidirectional then (1) layer of twill. This is about 10-12 layers.

Ran out of time and ended up hoisting the mast back onto the boat. I’ll finish up with about another 15-20 layers and some grinding and fairing.

Some freedoms had “running backstays” fitted for only for the use of free flying sails spinnakers , genekers ect . not a good idea in my opinion . these boats are fast enough without that risk. A

Former owner of Katorpus here—(Sold in April 2022)

Hull #61 Freedom 40 AC

Katorpus “came from the factory” with a mizzen staysail and running backstays. The head of the sail was attached to a halyard on the mizzen, the sail had a wire luff and was tacked to a ring on a sail track that ran fore & aft on the cabin top between the two main hatches. It was sheeted off of the end of the mizzen boom. Not something you wanted to use when doing a bunch of tacking back and forth, but…off the wind when you weren’t pointed down enough for a wing-and-wing, it would make a pretty good difference in speed on a long leg…

BTW, Adam…what sailor ever says his boat is “fast enough”? ![]()

Seeing those voids makes me wonder how TPI made them. I know with CF aircraft parts, they get bagged and vacuumed to make sure there’s no voids then cured in vacuum ovens.

The repair looks like it’s going really well. Did you find a new section of track?

conscientious cruising sailors without an unlimited budget generally think thus …

#1 safety

2 comfort

#3 not breaking expensive stuff on the way

#4 speed

cruising sailors are a completely different breed from racing sailors where speed is paramount , *what difference does it make if it takes 21 days or 25 as long as we were safe, comfortable and didnt break anything? "

vaimana’s mast was hand made 40 years ago vacuum bagging wasnt invented yet and neither was pre-preg Adam

I was finally able to finish the Vaimana’s mast repair on our spring break. I added the final carbon fiber layers (approximately 1/8-3/16”) and faired it with West System epoxy and fairing filler. I did a final 2 layers of fiberglass cloth over the whole damaged area, then a skim coat of more faring. I reattached the original aluminum slug track ( I had to “borrow” an 8” section from the bottom of the track near the gooseneck because I wasn’t able to source any ). I then added new Harken Battcar track. I also did a cosmetic repair to the original seam where the mast was made in 2 pieces. The mast was then painted and readied for stepping.

I was able to step the mast at the dock using the main mast 3 extra people and some tricky rigging. I tried to get a time lapse video of this but failed to start it properly. ![]() Other than that it went very smoothly. It took longer to clock it and get the mast wedge in place and compressed correctly than the whole raising process. We sailed around the islands in some rough seas and 20K wind without any issues.

Other than that it went very smoothly. It took longer to clock it and get the mast wedge in place and compressed correctly than the whole raising process. We sailed around the islands in some rough seas and 20K wind without any issues.

My plan is to sail back to Portland OR being very conservative reefing early and never with a full sail. I will then remove the mast and grind off the fairing coat from the whole length of the mast. I will add about 1/8 inches of carbon layers to the outside of the whole length of the mast in a controlled environment. I think that the current repair makes the mast stronger than the original, but it could just move the stresses above or below the break if there is some inherent strength issue with the mast. Adding the additional layers will make the whole mast stronger than the original, eliminating any reservations.

I still don’t know the root cause of this failure. One plausible theory is that the Vaimana has always been in a hot sunny climate, San Diego then Hawaii. Until the last couple of years the mast has been black making it get very hot in the sun. This thermal cycling is not good for composites; you basically get debonding between the epoxy and fibers. Another possibility is simply fatigue over the last 40 years. Or perhaps a combination of the two.

I will keep everyone posted on how the journey east goes scheduled around June 1

kevmec and adam, thanks for sharing this. Very useful info on a topic that I am sure more Freedom owners will need to confront at some point And impressive work on the repair done “in the wild”. Wishing you smooth sailing back to Portland.

Pleased to report that Vaimana is more than halfway from hawaii to portland , and the foremast repair is holding brillantly

Gents, Thx top info ; analyze in very short ……

-

My F44 masts are continuous UD carbon afaik. , so no 2 pieces with joint.

This is a typical East Coast rigged F44 with over-length even height masts , bar the extra bury of the mizzen mast over the mainmast it has equal sized mainsails, it runs a very large staysail , luff tensioned by runners to the very aft of the boat. So I would say ( for being a CB version ) its heavily canvassed. -

Iam astounded learning about this 2 piece construction on this F39 , ( because it’s a disaster in the making from start, imho unless heavily over- engineered , to avoid these very happenings.)

-

You cannot safely splice ( freestanding) carbon masts that way , you can however splice fully rigged carbon spars that way.

3a. Reason is ; you need the tensile strength of the carbon UD strand over the - full- length off the spar , this is precisely why you always want to avoid stress raisers ie. joints as described in the article.

4.Furthermore the void content in the laminate is very worrying , it look like a badly performed laminating job to me , ifaik 2 things ; 1 the UD is not laminated with proper longitudinal tension & the vacuum pressure has not managed to get rid of the air , if it was hand layup , it’s not de- aired properly. If it was resin injection , the flow was not ok ( flow mesh) . note ;longitudinal resin injecting UD is near to impossible as the flow takes the path of least flow resistance , meaning dry fiber spots & also voids due to improper stretching of the UD carbon strands , enabling the voids to form

Best method imho is prepreg carbon UD laminate and proper debunking ( getting air out before curing cycle ). But this system was not used much in the 70-80-ties .

Question ; does anyone have a ( F44 1985 )laminate scheme & resin spec. in their possession ? Secondly the method of layup ?

As I would love to run an actual composite calculation in our software , than we quickly learn the theoretical strength of these spars.

Respect to the owner in managing to perform a repair job outside a conditioned facility ![]()

Regards Sven Stevens

F44-CB # 22. ~Ape~

Azurspeed Design Group

Naval Architects , Marine Engineering

Aloha to all, Vaimana has just arrived safely to Portland after 23 days at sea , Hats off to Kevin, who not only removed and repaired and reinstalled the foremast of vaimana singlehandedly at the dock without the aid of a travellift or crane, but then proceeded to sail from Hawaii to Oregon by himself. Adam

Hats of to Kevin indeed. It has been a fascinating story to follow and happy to read such a grand finale. Thank you for sharing to tale.

Just getting started lol

I feel that it important to make a disclaimer at this point for all the owners of freedom boats/masts, throughout this whole process we have had the advice of eric Spongberg [ the original engineer and builder of freedom masts } as to the the layup and repair, and it was actually eric that caused us to go “public” in the first place, As for Kevin he is a mechanical engineer by degree and a carbon fiber fabricator by night , and a really really good dude too.

As Adam announced I did successfully make the 2300 NM crossing from Hawaii to Oregon and then another 95 NM up the Columbia River without incident. It was a 25-day journey. I was happy that the winds were light for most of the way as to not challenge the mast repair. I experienced several days of 18-20 knot winds with gusts to 25+ and 6-8-foot beam seas. I had the wind sensor mounted in a temporary position just above the radar mount about 10 feet off the water, so wind speeds were probably a little higher than measured. There was another day with 20-25 knot winds and whitecaps. At least they were on the forward quarter. I did have either a single or double reef in during these times. My original plan was to always have a reef in but quickly abandoned that as I couldn’t make reasonable progress below about 12 knots. Most of the time there was full sail up.

There is no evidence of cracking at the repair zone. I did notice that there is a slight crack at the original splice. I did do a minimal cosmetic repair in that area and wish I had ground and flared this region more. I cleaned then filled the seam (a butt splice) that looked like it only had fairing compound and removed about 8-10 inches wide of the fairing coat and layered unidirectional CF and weave. There is obviously movement still, as to Sven’s point a two-piece mast is not the best idea.

My long-term plan is to remove the mast again and grind off the outside faring coat and fiberglass winding. I will then add layers of carbon fiber in a controlled environment. My hope is that the resulting fix will be stronger than the original. I do worry that it won’t have the flexibility of the original design and the auto depowering will be different. Worst case I just reef more often.

I want to thank Eric Spongberg for his advice and support. We are lucky as a user group that he is willing to add his expert advice. Also, Adam has got to be the best previous owner any new boat owner could come across. His help, advice and outfitting of Vaimana has been over the top. Adam thanks for all the encouragement. Come visit anytime.

I’ll keep everyone posted of any new developments. Thanks for everyone’s input.

Here is a link to a video of full sail in about 12-15 knot winds. (I know I need to remove some rust then paint the collar).

https://www.dropbox.com/s/au0gz3550re5nnk/Video%20Jun%2017%202023%2C%206%2034%2015%20PM.mov?dl=0

shortly before the dismasting

shortly after